— A Comprehensive Guide for B2B Buyers From Lansulaser

1. Introduction:

In modern manufacturing, product identification is no longer optional—it is a core requirement for traceability, anti-counterfeiting, and brand protection. Fiber laser marking machines deliver high-speed, high-contrast, maintenance-light solutions that outclass inkjet, dot-peen, and label printing in both cost and quality. As a specialized Chinese factory holding more than 100 technology patents, Lansulaser designs and exports turnkey fiber-laser systems that help global manufacturers boost productivity while slashing operating costs.

2. Why Fiber Laser Marking?:

• Ultrafine beam quality (M² < 1.4) enables crisp micro-scale marks on tiny components

• Non-contact and consumable-free: no inks, acids, or solvents—just clean photons

• Permanent, high-contrast marks that resist abrasion, heat, and chemicals

• All-metal and most-plastic capability, covering everything from anodized aluminum to PC housings

• Easy automation: Lansulaser offers rotary units, conveyor integrations, and collaborative-robot cells

3. Key Technical Parameters (Lansulaser FL-Series):

Output power: 20 W / 30 W / 50 W / 100 W

Wavelength: 1064 nm infra-red

Pulse repetition rate: 1 kHz – 400 kHz (MOPA up to 1 MHz)

Peak pulse energy: ≤ 1 mJ

Marking speed: ≤ 7 000 mm/s

Repeatability: ± 0.01 mm

Standard marking area: 110 × 110 mm (optional 70 × 70 mm – 300 × 300 mm)

Cooling: air-cooled, < 800 W power draw

Control software: EZCAD 2 / LSL-Pro; supports Serial, PLC, Profinet, EtherNet/IP

Electrical: 110 V / 220 V, 50/60 Hz

Custom configurations—including dynamic-focus scan heads, IP-rated enclosures, and vision alignment—can be delivered in as little as seven working days.

4. Typical Marking Effects and Materials:

- High-contrast white or black marking on stainless-steel surgical trays

- Deep engraving up to 1.5 mm on tool-steel molds

- Color annealing on titanium watch bezels or rainbow stainless cutlery

- Day/night paint ablation for automotive interior buttons

- High-speed foaming on ABS or PC housings to create raised 3-D logos

- Micro QR / Data-Matrix codes as small as 0.5 mm² with 100 % first-read rate

Compatible materials include mild steel, stainless steel, aluminum, copper, brass, titanium, nickel alloys, chrome-plated parts, anodized or coated metals, ABS, PC, PA, PET, PBT, PPS, PVC, and selected ceramics.

5. Industry Applications:

Automotive: VIN plates, camshafts, dashboards, key fobs—zero-defect traceability meeting AIAG and VDA standards

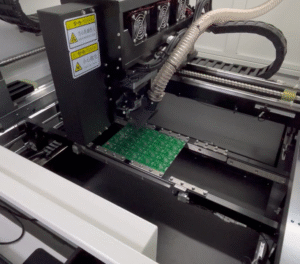

Electronics: PCB boards, USB housings, battery shells—micro-code serialization without damaging circuitry

Medical devices: surgical tools, orthopedic implants—UDI compliance with corrosion-free annealing on 316 L

Aerospace: turbine blades, nameplates—high-contrast IDs that survive extreme temperatures

Jewelry and luxury goods: watches, rings, pens—precision engraving plus multicolor decoration

Industrial tools: carbide bits, wrenches—deep etching for extreme wear resistance

Packaging and FMCG: aluminum cans, PET bottles—40 000 cans/hour date codes with no consumables

6. Automation and Integration Options:

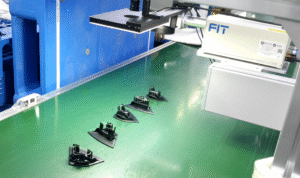

• Smart CCD vision for ± 0.02 mm auto-alignment on irregular parts

• Robotic loading with UR or FANUC cobots for unmanned shifts

• Conveyor fly-marking on-the-fly up to 120 m/min

• MES / ERP connectivity via Profinet gateway streaming live mark data to SAP or Oracle

7. Quality and Compliance:

Lansulaser is ISO 9001 registered and holds 100+ active patents covering optical isolation, power feedback, and dynamic focus control. Every FL-Series unit ships with a 48-hour burn-in log, optical-path alignment sheet, and CE-ready risk assessment. Global buyers benefit from a 3-year warranty on the laser source and galvo, remote diagnosis via smart-glasses, and spare-parts depots in Germany, the USA, and Malaysia.

8. How to Select the Right Model:

- Material and mark depth: aluminum logos use 20 W; steel engraving 0.5 mm deep starts at 50 W

- Cycle time: calculate required marks per minute and match wattage plus lens

- Marking field: larger F-theta lenses trade speed for area; ensure spot size meets code tolerance

- Automation level: desktop, enclosed stand-alone, inline conveyor, or robot cell

- Budget versus ROI: typical payback period is under ten months thanks to consumable savings and reduced scrap

9. Conclusion and Contact:

Fiber laser marking is transforming industrial identification with unmatched speed, durability, and flexibility. Whether you need to code automotive pistons 24/7 or engrave serial numbers on surgical scalpels, Lansulaser delivers configurable solutions backed by deep engineering expertise and responsive global service.

Contact us today for a tailored quotation and free sample test.

WhatsApp +86 18925707676

Wechat lansulaser668

Email info@lansulaser.com

Address Guangdong Province, Dongguan City, Tangxia Town, Lianhu Village, Baoyuan Road 3 (Lansulaser)