Printed Circuit Boards (PCBs) include various markings essential for identifying components, ensuring proper assembly, performing inspections, and maintaining full product traceability. As electronics become smaller and more complex, the need for accurate, durable, high-resolution PCB markings—especially QR codes—has increased dramatically. One of the most widely adopted technologies today is laser marking PCB, which ensures permanent and high-contrast marks suitable for automated production.

What Are the Markings on a PCB?

PCB markings are visual identifiers printed or engraved onto a board’s surface to guide assembly technicians, pick-and-place machines, engineers, and inspection systems. These markings play an important role in:

- Component placement

- Orientation alignment

- Quality inspection

- Testing and verification

- Production traceability

Clear PCB markings help prevent assembly errors, reduce repair costs, and support automated manufacturing.

Common Types of PCB Markings (Detailed Explanation)

1. Silkscreen Text, Labels & Symbols

Silkscreen printing is used to display basic information on the board, such as:

- Reference designators (R1, C5, U2)

- Polarity symbols (+ / –)

- Pin-1 indicators

- Connector labels (USB1, JTAG, FAN1)

- Test points (TP1, TP2…)

These markings guide accurate component placement and help technicians quickly identify parts during assembly and troubleshooting.

2. Brand, Version, and Regulatory Information

Many PCBs include important identifiers such as:

- Manufacturer logo

- Customer logo

- RoHS compliance marks

- Revision numbers

- Date codes

- Assembly batch codes

These markings help differentiate product versions and ensure regulatory compliance.

3. Fiducial Marks (Alignment Points)

Fiducials are crucial for SMT (Surface Mount Technology) assembly. They are small copper or bare-pad reference points used by pick-and-place machines for alignment. They ensure:

- Accurate component positioning

- Correct rotation detection

- Reduced placement errors

Fiducials are essential in high-speed automated production.

4. Barcodes & DataMatrix Codes

Barcodes and DataMatrix codes are used for internal tracking, inventory management, and quality control. However, they store limited data compared to QR codes.

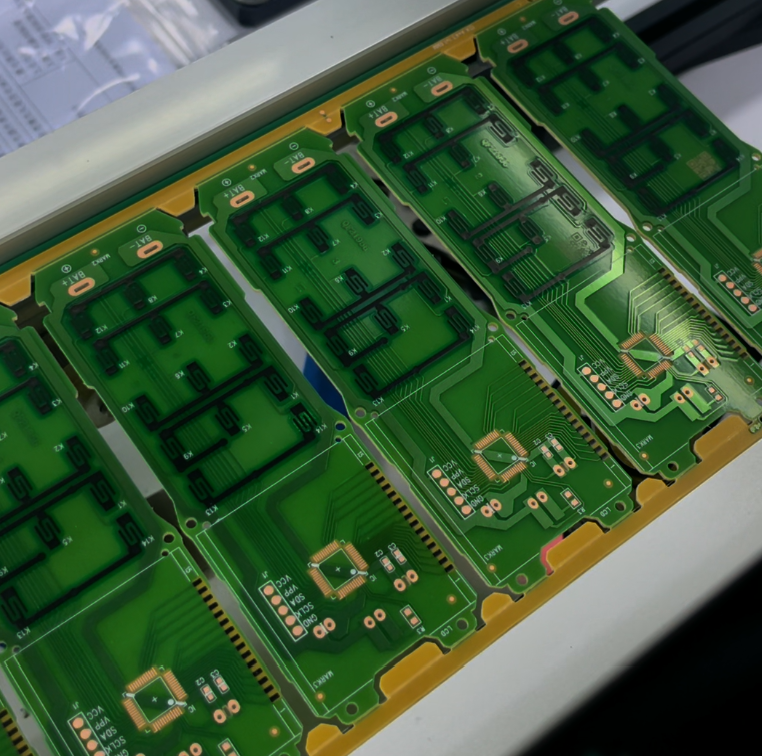

5. QR Codes on PCB (Most Important Today)

QR Codes have become the preferred method for storing detailed traceability information. A PCB QR code can store:

- Serial numbers

- Production date & time

- Inspection data

- Machine and operator ID

- MES traceability records

- Lifecycle history

Compared to barcodes, QR codes store more data in a smaller area and can be scanned in any direction.

To ensure readability, QR codes must be marked with extremely high precision—which is why laser marking PCB is now the global standard.

Why Laser Marking Is the Best Method for PCB QR Codes

Laser marking offers superior advantages over ink printing, stickers, or mechanical engraving.

Key Benefits:

- Ultra-high resolution (QR codes as small as 3×3 mm)

- Permanent and resistant to heat, chemicals, cleaning, abrasion

- Zero consumables (no ink, no labels)

- No damage to PCB copper layers

- High contrast suitable for AOI and MES systems

- Fast marking speed suitable for inline production

Laser marking is essential for modern electronics manufacturing, including smartphones, automotive electronics, smart home devices, computers, and industrial controls.

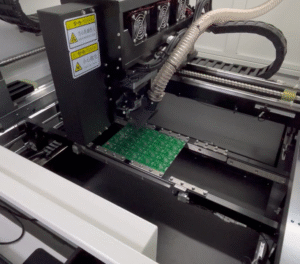

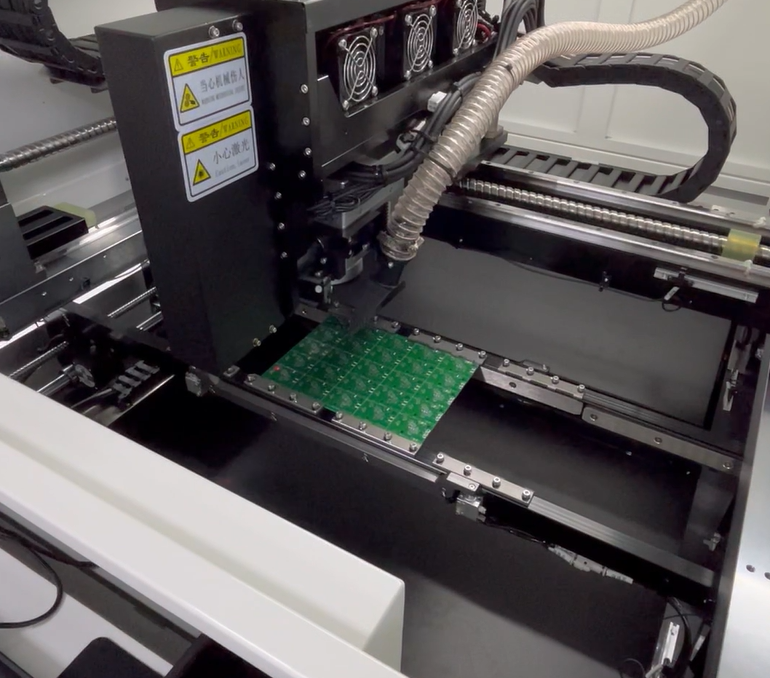

Introducing LansuLaser PCB Laser Marking Machine

LansuLaser provides an advanced PCB laser marking system designed specifically for high-precision, high-speed SMT production lines. By combining UV laser technology with CCD vision auto-positioning, the machine delivers stable, high-contrast marking across all types of PCBs.

Key Features

- High-resolution UV laser (355 nm)

- CCD automatic vision positioning

- Inline/Offline models available

- Permanent and high-contrast marking quality

- Compatible with MES and SMEMA

- Stable 24/7 industrial-grade performance

- Supports micro-QR codes, DataMatrix, serial numbers, logos

Technical Specifications

| Item | Specification |

|---|---|

| Laser Type | UV Laser 355 nm |

| Laser Power | 3W / 5W / 10W |

| Marking Area | 110×110 mm / 150×150 mm |

| Marking Speed | ≤7000 mm/s |

| Minimum QR Code | 3×3 mm |

| Positioning | CCD vision alignment |

| Cooling System | Industrial water chiller |

| Connectivity | MES / SMEMA |

| Operation | Inline / Offline automatic |

Compatible PCB Types

The LansuLaser PCB laser marking system supports marking on:

- FR4 PCB (green, blue, black solder mask)

- Aluminum PCB / Metal Core PCB

- FPC flexible PCB

- Ceramic PCB

- Thin PCBs for smartphones & wearables

- Multilayer PCBs

- Rigid-flex PCBs

UV laser technology ensures excellent contrast and durability on all materials.

Advantages of LansuLaser Laser Marking PCB Solutions

- Ultra-clear, high-contrast QR codes

- Zero damage to the PCB surface

- High-speed production capacity

- Fully compatible with SMT factory automation

- Zero consumable cost

- Long-term marking stability

- Supports QR code verification and MES uploading

- Ideal for mass production in electronics factories

Contact LansuLaser

Looking for reliable and high-precision laser marking PCB solutions?

📞 WhatsApp: +86 13825752051

📧 Email: info@lansulaser.com

🌐 Website: https://lansulaser.com

LansuLaser — Advanced Laser Marking Technology for Global PCB Manufacturing.