Precision and Traceability Define the Future of Electronics

As electronic devices become smaller, faster, and more complex, traditional printing and labeling methods can no longer meet the demand for durable and high-resolution identification.

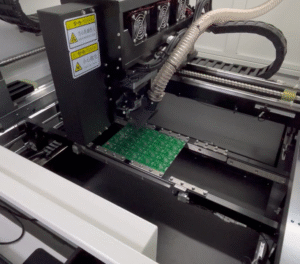

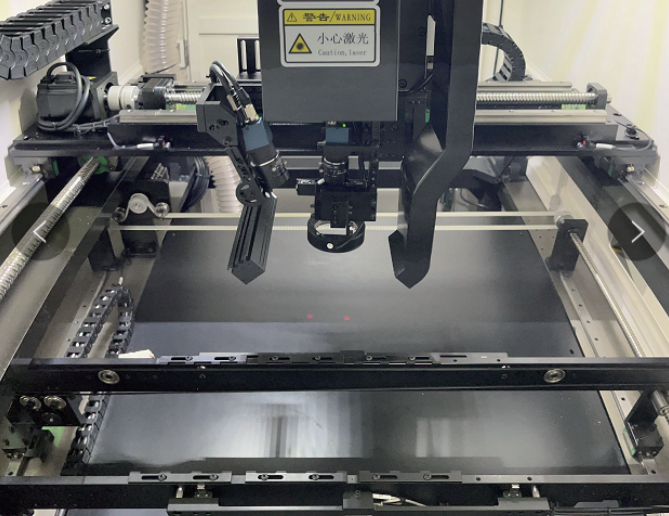

Laser marking PCB technology has emerged as the new standard. Using high-energy UV or fiber lasers, LansuLaser’s PCB laser marking machines deliver micron-level precision, non-contact marking, and permanent traceability, perfectly meeting the needs of Industry 4.0.

Why Choose Laser Marking on PCB Instead of Traditional Methods

Conventional methods like inkjet and screen printing are prone to smudging, fading, and low resolution. By contrast, PCB laser marking offers precise, clean, and permanent results with full automation compatibility.

High Precision for Miniaturized Components

The LansuLaser PCB laser marker achieves QR code, text, and serial marking as small as 0.1 mm, ideal for HDI boards, flexible circuits (FPC), and semiconductor carriers.

Permanent and Non-Contact Process

Laser marking directly etches the PCB surface without physical contact. The marks resist heat, abrasion, and chemical cleaning, ensuring readability throughout the product lifecycle.

Smart Traceability Integration

Each laser marking machine for PCB supports integration with MES, IMS, PMS, and ERP systems. It automatically generates serial numbers, links production orders, and uploads marking data for end-to-end traceability.

Eco-Friendly and Cost-Efficient

No ink, no solvents, and no consumables — laser marking reduces environmental impact and lowers operating costs by up to 40%, complying with ISO14064 green manufacturing standards.

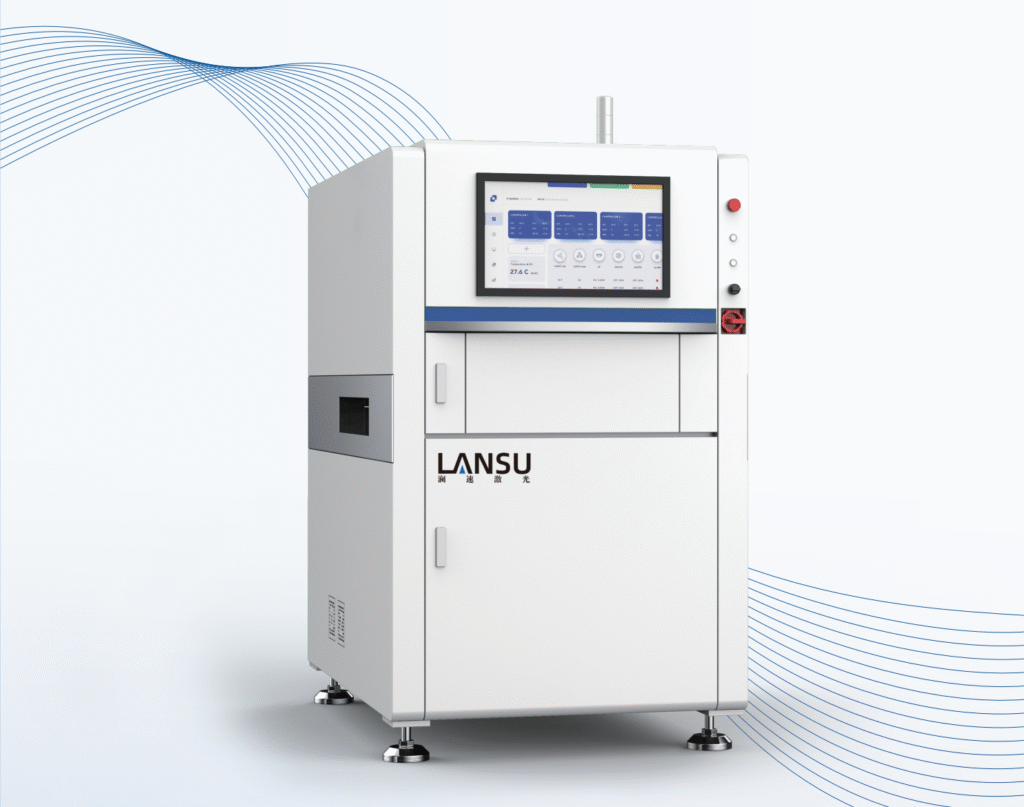

LansuLaser PCB Laser Marking Machines — Built for Industry 4.0

LansuLaser’s PCB laser marking systems are designed for inline automation with superior stability, speed, and accuracy. They are widely used in high-volume electronic manufacturing environments.

| Feature | Description |

|---|---|

| Positioning Accuracy | ±0.02 mm |

| Max PCB Size | 450 × 450 mm |

| Laser Options | UV / Fiber / CO₂ / Green |

| Cooling Method | Air / Water Cooling |

| Smart Camera | CCD visual positioning & 2D code verification |

| System Compatibility | MES / IMS / PMS / Database |

| Structure Options | Single-track, dual-track, 3-stage flip, double-sided marking |

| Marking Content | QR Code, Data Matrix, Text, Serial Number |

| Power | 2–2.5 kW |

Real-Time Quality Control

Equipped with intelligent CCD vision and automatic BAD MARK detection, the system ensures accurate marking and skips defective PCBs automatically.

Applications Across Industries

- Automotive Electronics

- Semiconductor Components

- Consumer Devices (Mobile Phones, Camera Modules)

- Medical Equipment

- Aerospace and LED Manufacturing

Wherever precision and reliability matter, LansuLaser’s PCB barcode laser marking ensures every circuit board is traceable and compliant.

Upgrade Your Production Line with LansuLaser

Join global manufacturers using LansuLaser’s PCB laser marking solutions to enhance traceability, quality, and productivity.

📧 Email: info@lansulaser.com

📱 WhatsApp: +86 18925707676

🌐 Website: lansulaser.com