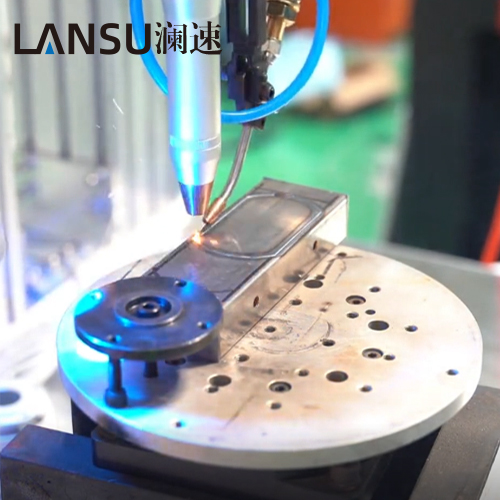

When it comes to the application of laser welding machines, we have to mention the mobile phone manufacturing industry. The manufacture of a mobile phone is not only the shell, the chip, but also various parts and components, and even a small camera. It can only be manufactured with unimaginable precision. The heat sink on the mobile phone parts is made of laser welding equipment with high enough precision.

The materials of these parts are generally metal materials such as aluminum and stainless steel. Because they are relatively fine small workpieces, the thickness will basically not exceed 3mm. The main processing difficulty lies in the accuracy and flexibility of welding. Everyone knows that the manufacturing process control of products such as mobile phones and tablets is very strict, and the requirements for welding effects are also high. Not only the welding effect needs to be beautiful, no porosity, no blackening, but also certain requirements for efficiency.

The light spot of the laser welding machine can reach 0.2mm, which will not cause deformation or other damage to the product, and uses cross cursors and red light to aim and position, and the pulse width range is 0.1~20ms. Few other welding equipment can achieve this level. It can not only ensure the accuracy of welding, but also ensure the precision of welding.

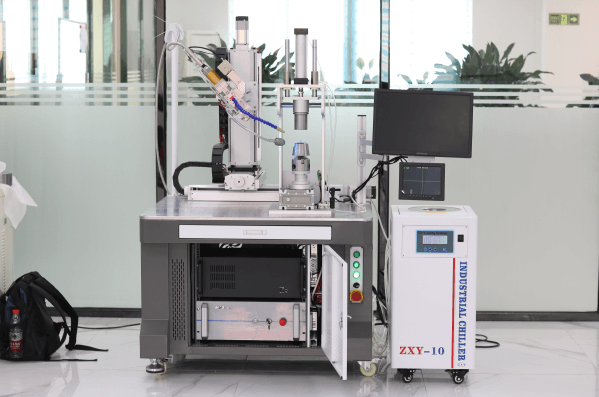

The laser welding machine is used for welding on the heat sink of mobile phone parts. It can adopt automatic welding method, and it is not too complicated. When a new equipment is first put into use in the factory, many production supervisors will worry that the employees below will not be able to operate it, resulting in The equipment is dusty, or it cannot perform as efficiently as it should. The operation of the laser welding machine is very simple, and the intelligent control panel is easy to detect, and it is also very friendly to novices!

The above is the welding effect of metal heat sinks. The same laser welding machine can weld more materials, not limited to heat sink materials. If you want to know the welding effect of other materials, you can consult the official website online customer service!