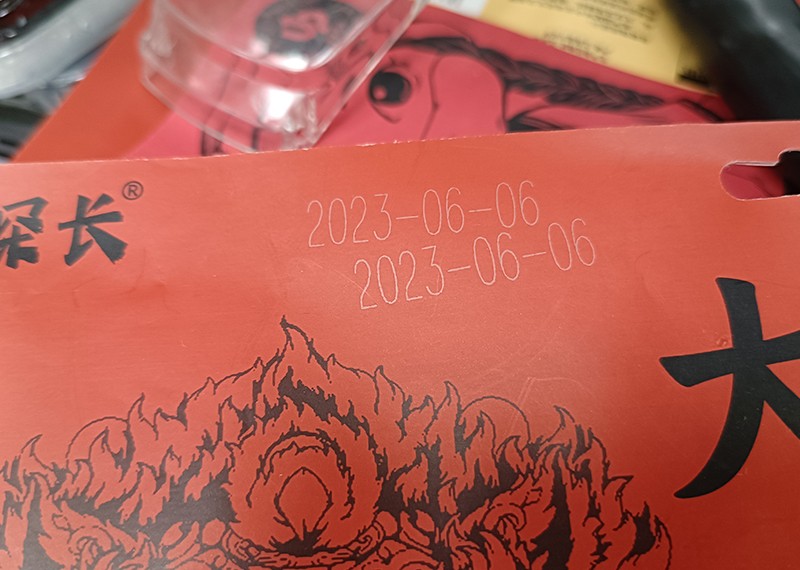

In our daily necessities, we can often see the batch number digital information on the plastic box. In the past, workers usually used ink or pigment to print these batch numbers, but the disadvantage of this method is that it is easy to blur and fall off. Now the characters on the box are not faded and are clearly visible, all thanks to the marking effect of the laser marking machine.

It is a very common case for a laser marking machine to mark on plastic. Generally, it can easily realize the identification of batch number, production date, bar code and two-dimensional code. Choose a suitable laser according to the type and requirements of the plastic. Different plastic materials have different absorption and reflection capabilities for laser light, so you need to choose a suitable laser wavelength and power. Adjust the parameters of the laser marking machine, such as laser power, frequency, and scanning speed, according to the characteristics of the plastic and the depth of the desired mark. Make sure the plastic surface is clean and smooth so the laser can interact with it better. Place the plastic on the workbench of the laser marking machine, and start the laser equipment to mark according to the position and content that needs to be marked.

It is worth noting that if the number of products to be marked is large and the delivery time is short, then a fully automatic laser marking machine can be used for marking in the selection of laser equipment. Its advantages are:

1. High efficiency and fast speed. It is a qualitative leap in efficiency and speed from manual marking machine marking 60-100 per hour to fully automatic laser equipment marking 6000-8000 per hour.

2. Cost saving. Reduced personnel expenditure, one employee can control multiple devices, greatly saving labor costs.

3. Reduce the error rate of marking and improve the utilization rate of products. Manual marking may cause placement problems and lead to wrong placement, which will cause a relatively large loss of products. Therefore, the fully automatic laser marking machine can automatically identify and mark, and mark any position at will.