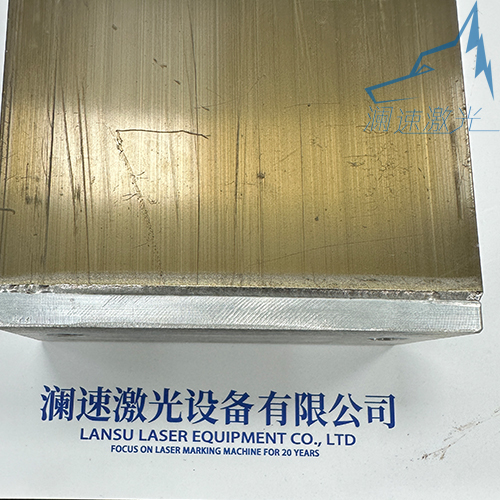

Brass, has always been an important processing material in industrial production, composed of copper and zinc, there are more than two elements of the alloy called brass, not only high strength, hardness is also large. Can copper materials be laser welded? This is OK, but relative to the same thickness of the metal material, the need for higher power is good.

In life or industry, valves, water pipes, radiators, and the connecting pipes of the internal and external machines of air conditioners, or bolts, nuts, springs and other structural parts are made of brass as one of the raw materials. Laser welding machines are widely used in these products, and laser welding of such small or medium-sized workpieces can improve the effect and efficiency.

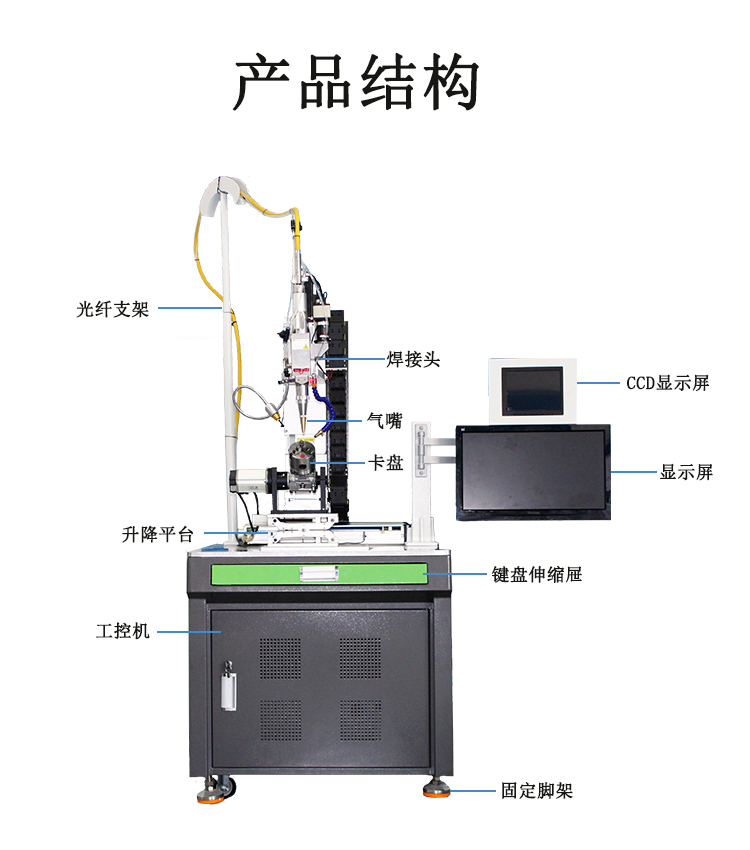

The working principle of the laser welding machine is to heat the metal surface through the laser beam energy, so that the welding position is melted to form a weld, so that the product can be processed in different welding methods (such as combination welding, overlap welding, composite welding, etc.) to achieve satisfactory results. For this kind of brass workpiece, there are also concerns about the model choice of laser welding machine. Some workpieces are small and delicate, high precision requirements, the use of automatic fiber continuous laser welding machine, platform; If the workpiece is very thin and the solder joint is very small, the choice of pulse welding is also appropriate.

These devices have a flat work surface for easy placement of workpieces; Intelligent control panel; High precision welding head; The flexible moving shaft is better than many traditional welding equipment with rigid operation in welding.

Laser welding machine also has incomparable advantages in the welding of brass products. The above mentioned laser welding accuracy is high, flexibility is strong, and it is better than other processes in welding effect, the operation is mainly machine, manual as a complement, the welding scar feels smooth, there will be no bubbles, cracks, deformation and other adverse phenomena!

In general, brass laser welding has certain advantages, especially some small brass workpieces or brass sheets with a thickness of about 0.3~5mm, and the welding effect is better!