Stainless steel is a raw material that will inevitably exist in the manufacturing of many products, and it is also a material that is often exposed to in laser welding processing. How can the welding effect of stainless steel laser welding machine be better? We will answer this question in detail from the aspects of selection, power selection, parameter adjustment and so on.

1, stainless steel laser welding machine selection:

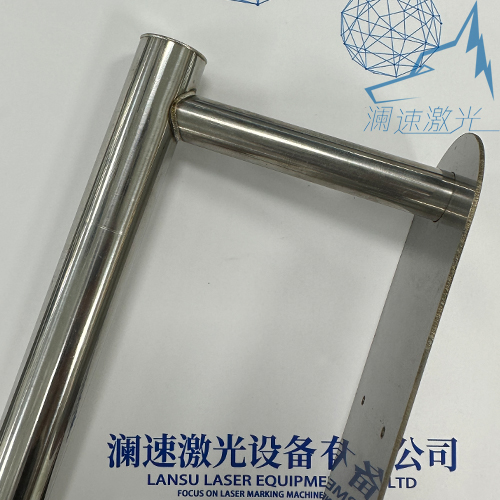

There are many models and styles that can be welded stainless steel, such as optical fiber continuous welding, hand-held welding, spot welding and so on, but there are great differences. First, from the size of the workpiece, if it is a micro, small workpiece, or a workpiece that needs to be fixed by the fixture, then choose the optical fiber continuous welding or spot welding with its own workbench and higher precision; If it is an ordinary stainless steel sheet, or pipe and other workpieces, you can choose a more cost-effective handheld stainless steel laser welding machine.

On the other hand, in terms of thickness, if it is a relatively thin material of about 1mm, use continuous welding or spot welding with higher accuracy, if it is 2-10mm thickness, you can use handheld.

2, stainless steel laser welding machine power selection:

Inappropriate power is not welding stainless steel material, a 5mm thick sheet you use 1000 watts of power for welding, the effect is not very good, not only welding opaque, welding scar is not good, so choose the right power, the welding effect of stainless steel plays a key role. The commonly used power of this hand-held model is 1000 watts, 1500 watts, 2000 watts, and the thickness is suitable for 1-2mm, 3-5mm, 5-7mm; The common power of optical fiber continuous this model is from 1000 watts to 6000 watts, and the common power of spot welding this model is 200 watts and 400 watts, and the specific thickness needs professional technicians to test and recommend. In general and handheld thickness corresponding power is not much different.

3, stainless steel laser welding machine parameter adjustment:

This part is related to professional practical application experience, welding on the choice of gas, welding Angle, welding wind and ventilation are required, the more detailed the adjustment, the better the effect of welding, which is why the need for proofing testing, only the actual proofing, in order to know what kind of parameters for your material. Of course, when docking with the stainless steel laser welding machine manufacturer, the manufacturer will adjust the appropriate parameters for you, and it will also be targeted after being put into use, and there is no need to worry about this.