The galvanized pipe on the market generally has a yield strength of more than 300MPa, high toughness, good welding performance and cold forming performance, the use of laser welding machine for welding processing can often achieve good results, most of the welded hot-dip galvanized steel pipe this type.

Hot-dip galvanized pipe has a wide range of uses, and it has strong corrosion resistance. Some construction, machinery, coal mining, electrical, chemical, container and other industries often use this metal pipe, and the application range of laser welding machine has no small overlap. Laser welding machine because of its high welding accuracy, flexible welding methods, environmental protection, good effect and other advantages in mechanical equipment, 3C electronics, mechanical and electrical, chemical, pipe, aerospace and other industries have significant applications.

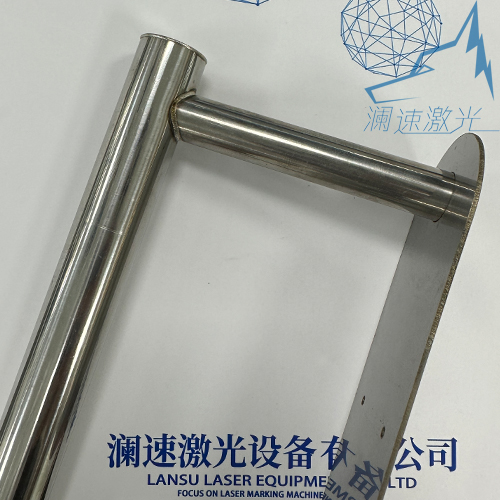

Laser welding machine can generally be welded in the thickness range of 0.3mm~10mm, and the wall thickness of galvanized pipe is mostly 2.0, 2.75, 3.5, 4.0, 4.5, etc., this kind of thickness of the pipe with laser welding equipment processing is very suitable, handheld laser welding machine can be welded on the galvanized pipe once forming, the weld is also beautiful, Generally few welding slag splash, will not lead to pipe deformation, perforation, foaming, etc., we all know that the weld welding effect of the pipe has an impact on the overall quality of the product, and the effect of laser welding makes the galvanized pipe more points!

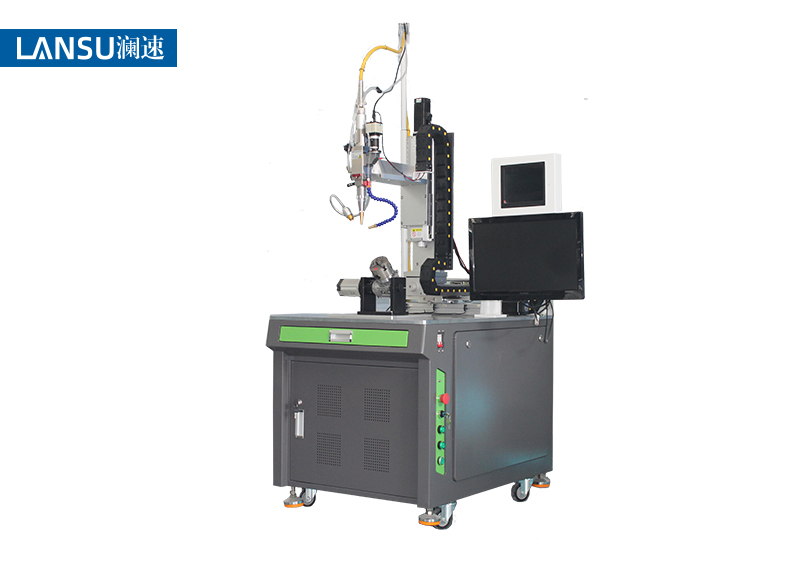

Welding galvanized pipe handheld laser welding machine is better, the robot type can also be, in the welding operation is relatively simple, generally a few hours can be proficient in hand welding, the operation difficulty of ordinary employees is not high, which is also one of the reasons why laser welding function is widely used in various industries.