Laser spot welding machine is mainly for some micro and small workpieces, parts, or metal sheet welding, such as USB interfaces, electronic components, hardware molds, gold and silver jewelry, etc., to achieve all kinds of combination welding, overlap welding, dot, repair welding, etc., 0.3mm thickness of the brass sheet is usually used for spot welding pulsed laser welding machine.

Laser spot welding machine is mainly composed of laser, power supply and control, cooling machine, light guide and focusing, binocular stereo microscope observation several parts, compact structure, small size. The working principle is to use high-energy laser pulses to locally heat the material in a small area, and the energy of laser radiation diffuses to the interior of the material through thermal conduction, melting the material to form a specific melt pool.

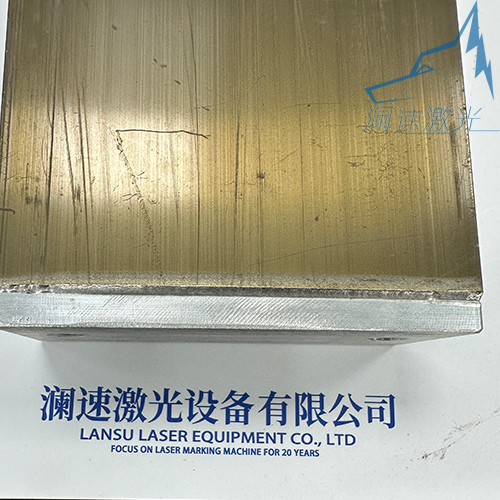

If the 0.3mm brass sheet is used in other welding processes, it is easy to be directly broken down, or the solder joint is too wide and the welding power is too large, resulting in black deformation of the solder joint, and there are few welding methods that meet this demand. Laser spot welding machine stands out among them, can accurately spot welding on the brass sheet, welding position, beautiful welding spot, fast welding speed!

Laser spot welding machine after continuous development, a variety of models, in order to meet the different needs of users, extend some more convenient configuration, in improving the welding effect and efficiency has a significant effect. For example, some XYZ three-axis platform, boom laser spot welding equipment, etc., it is because the application industry in contact with such needs, these styles will come into being, and these special configurations also allow the laser spot welding machine to provide greater help for enterprises in processing.