Galvanized sheet refers to the surface coated with a layer of zinc steel plate, with better corrosion resistance, paint, formability, is not only an economic and effective rust resistant steel, but also very conducive to welding processing, very wide range of uses, usually used in small household appliances industry, machinery and equipment industry, construction industry, automobile manufacturing industry. Galvanized sheet welding is generally used handheld laser welding machine, simple operation, fast speed, welding thickness of about 1mm~10mm.

Laser welding is a high energy beam welding technology, with high energy density, high welding efficiency, weld depth to width ratio, small heat affected zone and thermal deformation, energy saving and other advantages, very suitable for the requirements of fine welding technology, but also more research, the actual production and processing process is widely used in a welding method. Fiber lasers have the characteristics of high photoelectric conversion efficiency (generally up to 35%), long service life, stable energy, good beam quality, and have been widely used in laser welding machines, and are very advantageous in galvanized sheets.

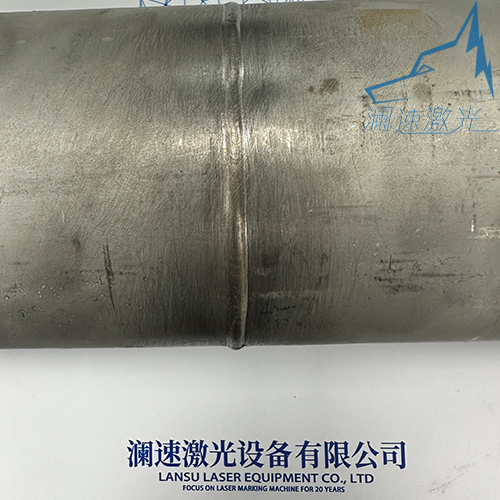

Laser welding machine is unilateral processing, complex structure adaptability, easy to achieve remote welding and automation. The welding coating zinc loss is low, the operation is simple, the weld is smooth and does not blacken, and there is no need for secondary grinding, which can save the secondary grinding cost and labor cost to a certain extent.

If there are higher requirements for welding efficiency, it is recommended to use a robot laser welding machine, which is commonly used for automatic outer fillet welding of galvanized plate box, good weld sealing, no water leakage, basically no grinding, no one is involved in the welding process, and can be applied to mass production.