Industrial aluminum profiles are generally used as mechanical equipment, door and window handrails, a variety of electronic equipment and daily supplies of material accessories appear in front of everyone, the material welding processing and forming can not be separated from laser welding machine, aluminum profile welding should be how to choose the right welding machine? Read the following and you will understand!

General traditional welding processes, such as argon arc welding, cold welding, touch welding, etc., can weld aluminum profiles, but they have advantages and disadvantages. Welding effect is good, loud noise, welding slag splash, low efficiency, technical requirements for workers, not environmental protection, high welding efficiency, in the effect can not meet the requirements, in recent years, the rise of laser welding machine, so that more people have a deeper understanding of this welding process and application, the sound of praise gradually catch up with the traditional welding process.

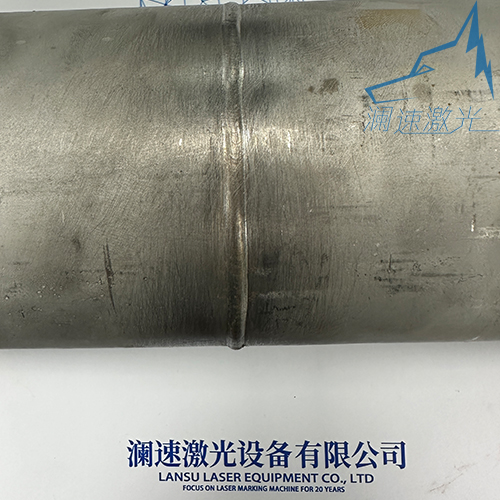

If your aluminum profile thickness is in the thickness range of 1mm to 10mm, the workpiece is a common aluminum sheet, aluminum tube, hardware tools, or some daily pallets and other products, then you can try to use laser welding machine for welding processing. Laser welding refers to the use of high-speed moving laser beam irradiation on the surface of the material to be welded, so that the laser and the welding material have a strong interaction, resulting in melting, gasification and other instant physical and chemical processes. Laser welding speed, weld depth to width ratio, good welding quality, high degree of automation and low production cost, especially suitable for thin plate welding between dissimilar materials.

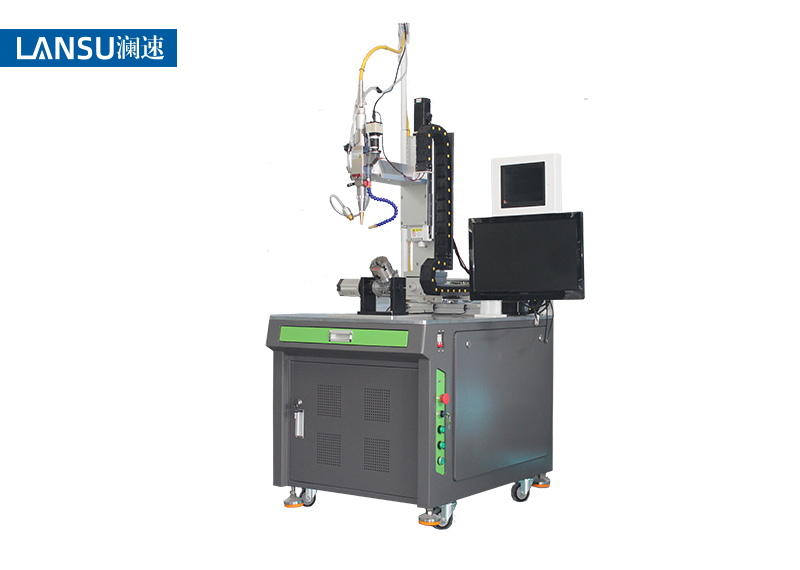

Aluminum profile welding can be used handheld laser welding machine, can also be applied fully automatic laser welding machine, handheld laser welding machine need manual welding, basically welding a molding, welding effect is beautiful, suitable for aluminum plate welding. If it is a more complex aluminum workpiece, you can choose a fully automatic style, fixture fixing, robot automatic positioning welding, solder joint accurate, high welding accuracy, saving time and effort!