Before understanding the automatic laser marking machine, we first take a look at the traditional marking technology: screen printing, ink inkjet, manual engraving, printing, etc., these methods are not only slow marking speed, but also more consumables in the marking process, the rate of defective products is higher, mainly the effect of the marking is not fine, can not achieve the current pursuit of high quality products.

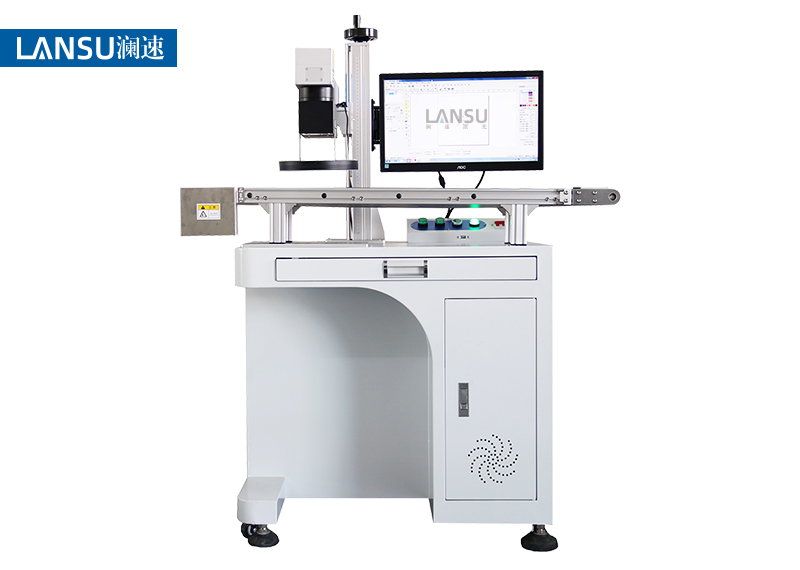

Automatic laser marking machine is a marking equipment using laser technology. Compared with the traditional marking method, laser marking has the advantages of high precision, fast speed, good effect and no physical damage to the workpiece. In the headphone manufacturing industry, laser marking machines can quickly and accurately imprint logos, serial numbers or other identifying information on headphone components.

The operation process of the automatic laser marking machine is relatively simple, from the previous marking 600 an hour to the present marking 8000 changes an hour. Generally, the following steps are involved:

1, first need to mark the earphones into the equipment tray, through the program to control the material circling, you can batch the earphones to the marking position;

2, and then through the laser controller to emit a laser beam, the earphone surface engraving;

3, through the image processing system to detect and correct the engraving results, to ensure the accuracy and clarity of the mark.

4, in the entire operation process, it is necessary to pay attention to the adjustment of the laser energy, the control of the marking time and the accurate control of the headset position.

Automatic laser marking machine is of great significance in the batch identification of headphones, which is changed from the quality and quantity at the same time, it can not only improve production efficiency, but also improve product quality and reduce the scrap rate. For those manufacturing companies that are looking for new marking methods, automatic laser marking machines are undoubtedly an option worth considering.