The mobile phone manufacturing industry is a big industry with a very large demand for welding, including many welding processes, such as mobile phone frame welding, camera welding, spare parts welding, USB interface welding, etc. Today, we are talking about the mobile phone frame laser welding machine is a very superior performance of a welding equipment, but also the mobile phone manufacturing industry's favorite new welding equipment.

In the welding process of the mobile phone frame, many factories are still using traditional welding equipment, but the traditional welding method is not beautiful, the heat affected area is large, and it is easy to deform the outside of the product, and it is easy to de-weld. On the other hand, the efficiency is also relatively difficult to keep up, and the rework rate is high. Laser welding has small heat affected zone, small deformation, fast welding speed, smooth and beautiful weld, which is suitable for welding of various parts of mobile phone.

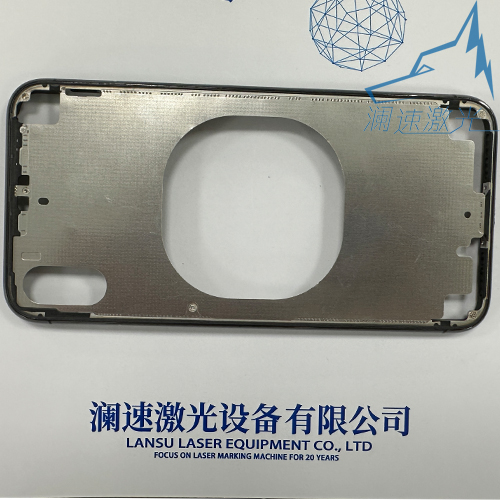

The application of the laser welding machine in the outer frame and shrapnel of the mobile phone, that is, the mobile phone shrapnel, like the hub connecting 4G and 5G, the aluminum alloy frame and the other material structural parts of the plate are connected to the mobile phone, the laser welding precision is high, the weld is smooth and smooth, there is no deformation and blackness, and the material can be easily welded and beautiful.

Mobile phone frame laser welding machine can use visual positioning spot welding, welding CCD for coaxial monitoring; The welding operation is simple, the laser head life is long and the maintenance is convenient. Laser processing constant temperature control, laser processing point real-time temperature monitoring. Closed-loop feedback, solder joint adjustable, better adapt to different solder joint size requirements, compared with other traditional welding equipment, laser welding on micro materials or small products can be described as handy.

In the aluminum alloy mobile phone frame welding, mobile phone frame laser welding machine advantages are obvious compared with the traditional welding method, high production efficiency, and no need to fill wire; It can solve the defects generated after welding, such as cracks and pores splashing, etc., to ensure the good mechanical properties of aluminum alloy after welding; It will not sag after welding, and the amount of polishing after welding is reduced, saving the production cost.