Laser welding machine is a processing tool specially used for welding metal materials, of course, can be applied to stainless steel welding, mainly can weld stainless steel sheet materials with a thickness of 0.15mm-10mm.

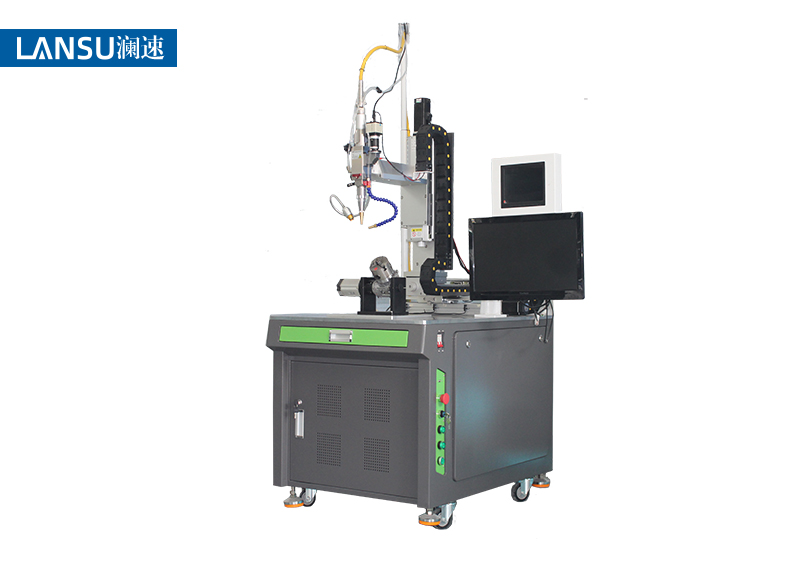

Laser welding machine is a kind of high-tech equipment, it can use high energy laser beam to weld metal materials, has the advantages of high efficiency, good effect and high precision.

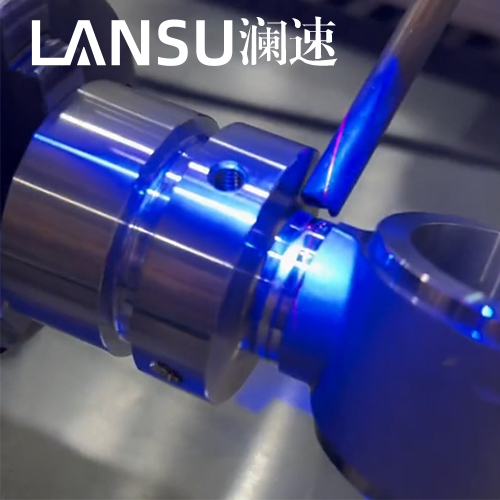

Compared with carbon steel, stainless steel is easier to obtain deep weld because of its low thermal conductivity, high energy absorption and melting efficiency. By welding thin sheet with low power laser welding, the joint with good shape and smooth and beautiful weld can be obtained.

Stainless steel welding can of course be laser welding, the advantage of laser welding is that the cost and time can be greatly reduced. The laser welding machine produced by the company can weld a variety of metal materials, the size of the laser welding machine is 200W to 6000W, which can fully meet the welding of various metal materials, models and styles are complete, to meet the needs of different stainless steel welding.

So, how does the laser welder weld stainless steel? First of all, it is necessary to prepare the stainless steel and clean its surface to avoid problems such as oxidation, discoloration, and splashing of welding slag during welding. Then, the stainless steel is placed on the welding machine workbench, adjust the parameters of the welding machine, such as power, speed, etc., and begin to weld. In the welding process, it is necessary to pay attention to maintain the stability of the welding area to avoid deviation during welding.

In short, laser welding machine is a widely used in stainless steel material processing of high efficiency, high intelligence, high precision, controllable welding method, through reasonable welding parameter Settings and technical control, can achieve a variety of stainless steel materials of high quality welding connection.