Laser welding machine as an increasingly powerful welding processing equipment, the volume of discussion in all walks of life is getting higher and higher, and we are also exploring its more possibilities, such as its advantages in aerospace. Metal laser welding technology is increasingly emerging as the future light of aerospace wing manufacturing. This paper will deeply discuss the key role of metal laser welding in aerospace industry manufacturing and its future development prospects.

In the field of aviation manufacturing, laser welding technology is mainly used for the welding of special aviation materials, such as titanium alloy, aluminum alloy, nickel alloy, chromium alloy, stainless steel, beryllium oxide, composite materials, electronic components and so on. The aerospace parts machined by laser welding include engine flame cylinder, titanium alloy thin-walled casing, aircraft frame, titanium alloy skin, wing girder, tail panel, helicopter main rotor and so on.

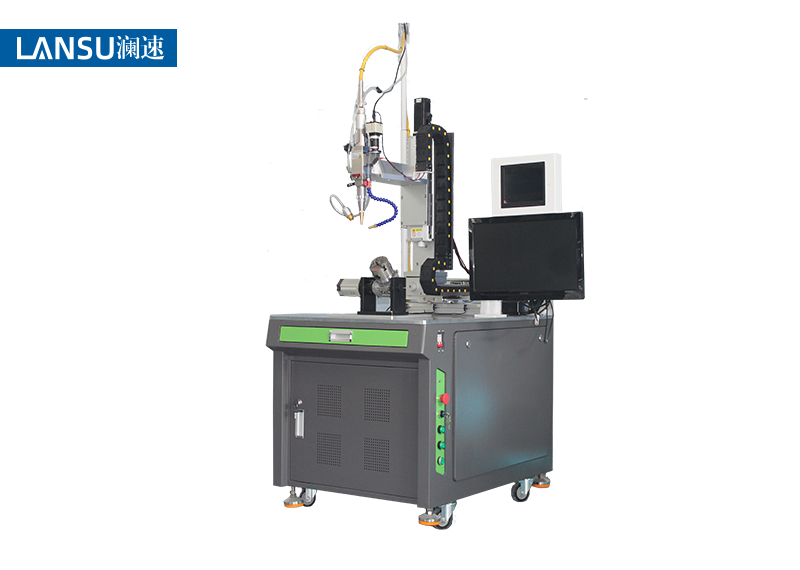

The lack of automatic production capacity has become a bottleneck restricting the improvement of the reliability and production capacity of weapons and equipment. Under the background of the era of vigorously developing aerospace in China, the application of industrial robots in automated production by aerospace manufacturing enterprises is of great significance to the transformation and upgrading of enterprise production mode and the improvement of equipment advanced manufacturing capacity. The robot laser welding machine is generated for the needs of automated production, and the welding efficiency of metal materials is a new promotion.

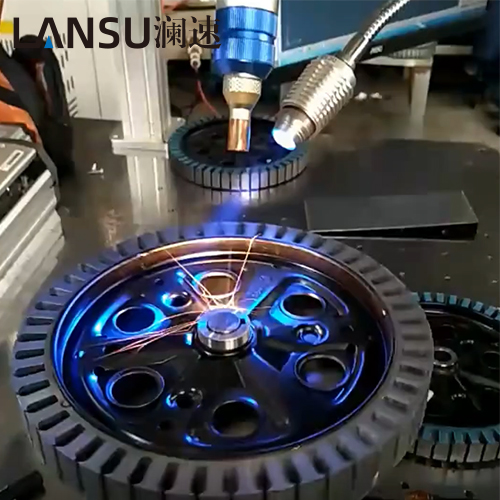

The working principle of the laser welding machine is to use the high energy and high focusing of the laser beam to heat the welding material to a molten state, and then cool and solidify, so as to complete the welding work. Compared with traditional welding methods, laser welding can obtain higher welding quality and smaller heat affected zone, without the use of welding auxiliary materials, will not pollute welding materials, so it is widely used in many fields.

In short, laser welding machine is a high-precision, high-efficiency welding equipment, with high precision, fast speed, small heat affected zone and other advantages, is widely used in automotive manufacturing, aerospace, electronic instruments and other fields.