Acrylic sheets, with their transparent texture, are widely used in various display racks, decorations and other occasions. During the production process, it is often necessary to carve various patterns or logos on acrylic sheets. So, can we use a laser marking machine to engrave on acrylic panels?

First, let us understand how the laser marking machine works. Laser marking equipment uses high-energy laser beams to irradiate the surface of an object, causing the material on the surface to quickly melt, vaporize or change color, thereby leaving a permanent mark on the surface of the object. It has a wide range of applications and can mark metal materials and most non-metallic materials. It can be said that most common materials in the manufacturing industry can be marked with laser equipment.

Next, let’s look at the characteristics of acrylic panels. Acrylic sheet is a transparent plastic sheet whose chemical composition is polymethylmethacrylate. When this material is irradiated with high temperature or high-energy laser beams, it undergoes a chemical reaction and gradually decomposes into low-molecular substances.

Based on the above two points, we can conclude that the laser marking machine can engrave on acrylic plates. However, it should be noted that due to the low melting point of the acrylic plate, when engraving with laser marking equipment, the laser power and engraving speed need to be controlled within an appropriate range to avoid melting or ablation of the acrylic plate. In addition, choosing the right model and power is also important, otherwise you will get an explosive marking effect.

It is usually recommended to use a carbon dioxide (CO2) laser marking machine to engrave acrylic plates. The engraving effect will be clear and smooth, with uniform thickness. Generally, the engraving color is the original color of the material. The advantage is that it will not fade unless the product is seriously damaged. The logo can be maintained for a long time, and the laser marking method is environmentally friendly and fast. The marking content and marking efficiency can be controlled by adjusting parameters.

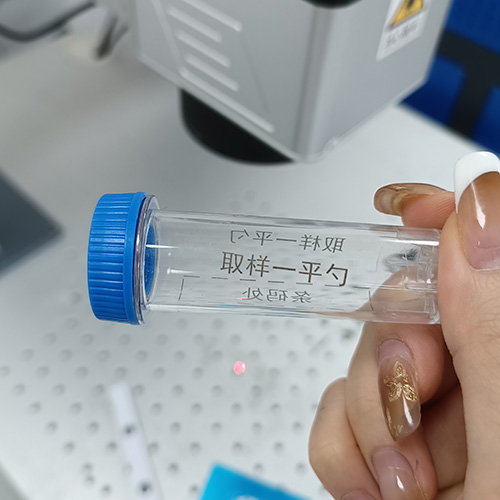

In general, laser marking machines can engrave on acrylic sheets. But in actual operation, we need to conduct a proofing test first to obtain more accurate marking parameters and power, so as to ensure the engraving effect.