When many users purchase laser equipment, if they only have a little knowledge, it is difficult to choose a suitable model, and it is easy to get into trouble. So, what are the core accessories of laser marking machines? This article will introduce it to you in detail.

1. Laser

The laser is the core component of the laser marking machine, which is responsible for generating the laser beam. The main performance indicators of lasers include output power, wavelength, beam quality, etc. The types of lasers generally include optical fiber with a wavelength of 1064nm, CO2 with a wavelength of 10640nm, purple light with a wavelength of 355nm, etc. How to choose directly affects the marking effect and production efficiency of the laser marking machine.

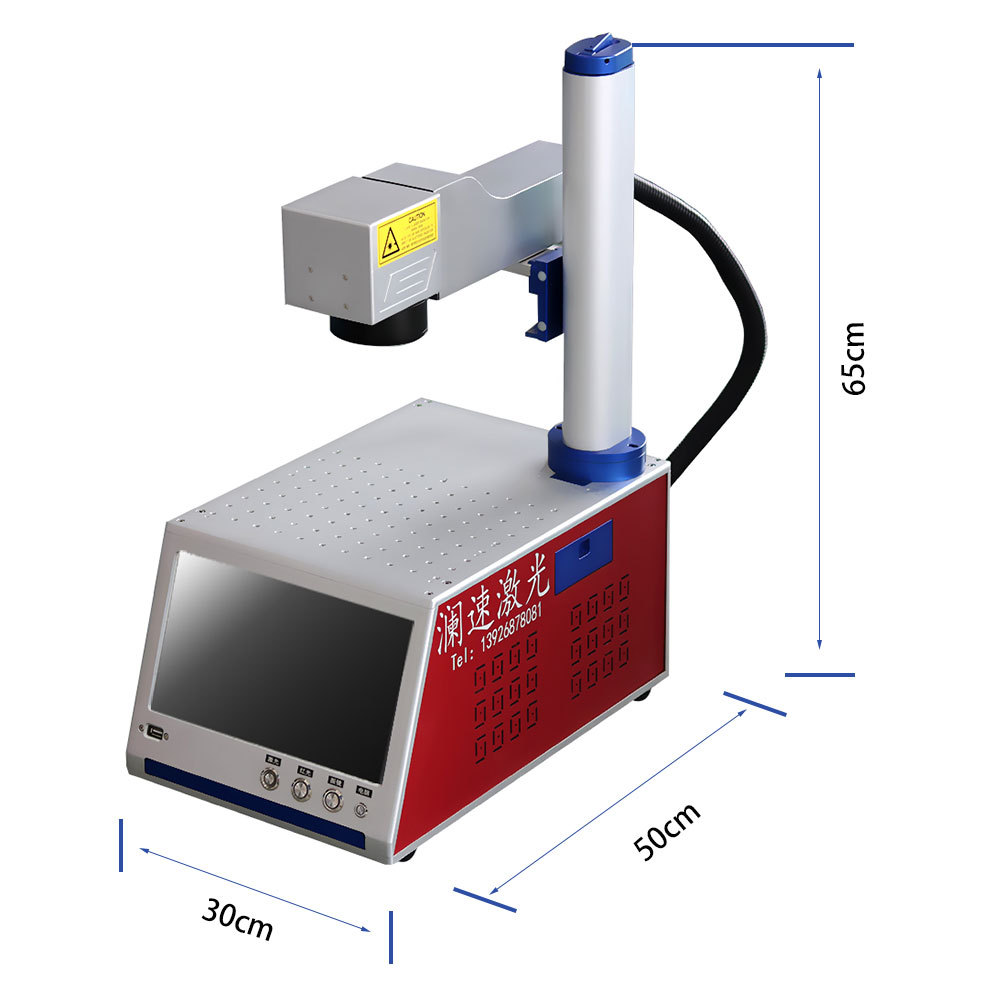

2. Workbench

The workbench is mainly used to place the workpieces to be marked. The workbench usually adopts a metal mechanical structure to ensure the stability and accuracy of the workpiece during the marking process. At the same time, the workbench also has functions such as automatic feeding and positioning to improve production efficiency and marking quality. Of course, if it is a handheld model, there is no need for a workbench.

3. Cooling system

The laser marking machine will generate heat during work, especially in summer. If it cannot be effectively cooled, it will easily affect the function and service life of the laser marking machine. Therefore, in order to ensure the stable operation of the laser marking machine, the cooling system usually Use water cooling or air cooling to dissipate heat from key components to prevent equipment damage or performance degradation caused by excessive temperature.

4. Control system

The control system is the "brain" of the laser marking machine. The effect of the product's logo is closely related to the control system of the laser marking machine. It is responsible for controlling the switching of the laser, the movement of the optical scanning system, the positioning of the workbench, etc. The control system usually uses PLC or industrial control computer as the core, and achieves accurate control of the laser marking machine through programming. Its human-computer interaction settings are highly flexible and convenient for users to set parameters and operate.

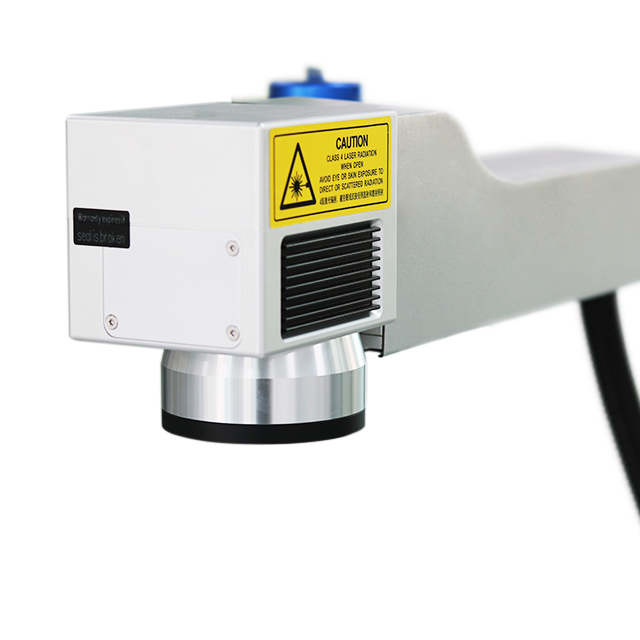

5. Optical scanning system

The optical scanning system is responsible for scanning and focusing the laser beam generated by the laser to form the required marks on the surface of the workpiece. Optical scanning systems usually consist of scanning galvanometers, focusing mirrors and beam expanders. The scanning galvanometer is responsible for controlling the scanning direction and speed of the laser beam, the focusing mirror is responsible for focusing the laser beam onto the workpiece surface, and the beam expander is used to adjust the diameter of the laser beam, which also determines the marking range of the laser marking machine. (The standard range is 150*150mm).

To sum up, the core accessories of laser marking machines include lasers, optical scanning systems, workbenches, control systems and cooling systems. The collaborative work of these core accessories allows the laser marking machine to perform superior performance in various industrial production scenarios.

As a laser marking machine manufacturer, we also recommend that when choosing a laser marking machine, you should choose suitable core accessories based on your own production needs and processing requirements. On the one hand, you can achieve high cost performance, and on the other hand, you can achieve better performance. Meet your own marking needs.