With the continuous development of science and technology, standard manual identification has not been able to meet the needs of enterprise intelligence, mechanization development, now industrial production for efficiency and intelligent requirements are increasingly high, many enterprises followed by process reform, laser marking machine in 3C electronics, automobile manufacturing, hardware tools, smart home and many other aspects have no small use, Mainly used in the product production date, LOGO, parameter model, two-dimensional code bar code, use information and other content. Because of its combination of assembly line production, code jumping marking, error prevention and stay, two-dimensional code marking detection, much loved by the factory, automatic loading and unloading laser marking machine is one of the factory adaptability is very high marking equipment.

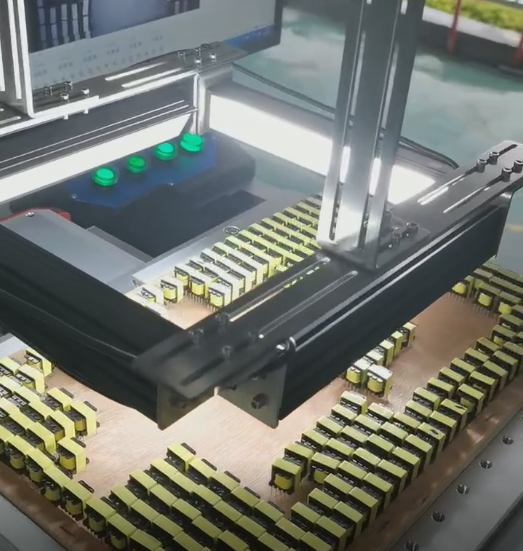

The following is the automatic loading and unloading laser marking machine combined with the assembly line, vibration disc and other devices, so that the factory's original manual loading and artificial placement position into a machine using the assembly line and vibration disc to orderly product transmission to the laser one by one. Products from the previous process of transmission belt transmission down, without manual placement, through the automatic correction of the "vibration disk", the product will be automatically ordered, one by one transmission to the laser marking machine process. Conveying to the laser head below, laser marking machine CCD visual detection system will be in a few tenths of a second after the "product shooting - identification and positioning - operation marking", marking and editing good content in the product. Without manual participation in the whole process, the product will be marked after the automatic delivery of the next process through the pipeline.

Automatic loading and unloading laser marking machine is Dongguan LAN speed laser equipment manufacturers in order to more comply with customer marking needs and continuous research and development, testing and manufacturing of a new generation of automatic laser marking machine, it alleviates the factory recruitment difficulties, intelligent production on the one hand can reduce labor cost input, on the other hand is greatly improve the efficiency of the factory and yield. The improvement of efficiency makes enterprises more confident and bold to receive more orders, thus increasing more profits for enterprises. With the products produced, customers no longer have to worry about frequent rework due to the blurred logo; There is no need to worry that the production capacity can not keep up with the delivery date, and the overtime will affect the production plan.

Of course, automatic loading and unloading laser marking machine for the product has certain limitations: Not suitable for large product identification, because the vibration disk has a certain diameter, can only accommodate small volume of products, combined with the production line can reach 10000 / hour marking efficiency, if you have similar products, want to know more about the relevant information, you can consult online customers, you can also call us, LAN laser to provide free sample, free out of the program and other services.