Recently, we have many customer inquiries from the motor industry. These customers used to use traditional technology. When they came to Lancu Laser factory to visit the trial machine, they all had great interest in laser welding machine. And said that if the laser welding machine can successfully participate in the production line use, it will have a huge impact on their production efficiency and welding effect.

Why does laser welding machine attract the attention of this industry? Why are so many industries abandoning traditional welding processes and switching to laser welders? I believe many factories are suffering from this: ordinary staff always because of development or emotional factors such as high turnover rate, difficult to recruit workers has become a big problem for factories. The use of automated mechanical work has a good coordination effect, is not affected by human factors, and can be quickly applied to different workplaces, greatly reducing the impact of human factors on delivery and welding effect. Can not be said to completely abandon the operation of personnel, but the laser is its main function, and the operation is very simple, usually need staff careful operation of equipment, after the use of laser welding machine, only need to intelligent welding equipment for simple care, reduce the demand of professionals pressure.

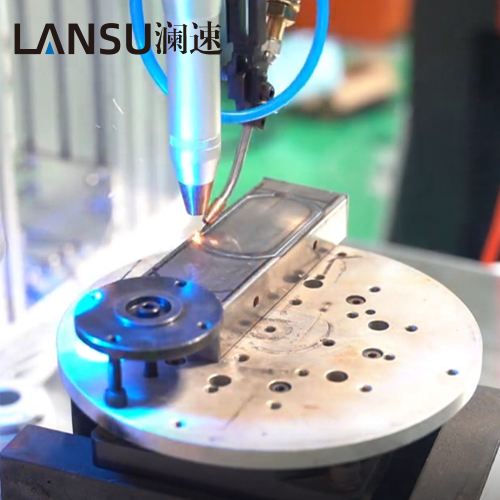

The operation of laser welding machine is simple, do not need experienced master looking at welding and operation, and the melting depth is relatively deep, 1-5mm can be welded through, welding speed is relatively fast, can guarantee the continuous operation of 24 hours, more easy to cooperate with computer numerical control system or manipulator, robot and other configuration, to achieve multi-axis automatic welding, improve production efficiency. In general, a laser welding machine from saving labor, improve the welding effect, reduce the rework rate is a kind of efficiency. Intelligence is a trend of the industry, but also a way to improve efficiency and save labor.

And the laser welding technology has many advantages, such as no mechanical contact between the welding device and the welding parts, reduce the pollution to the workpiece; Heating concentration, high energy density; The heat affected zone is small, resulting in less thermal deformation and thermal damage. Beautiful weld, high weld strength; Through numerical control, can accurately control the energy output, welding speed, high productivity. Although the cost of laser welding machine is too high, but in terms of production and cost benefit, production can be increased to earn much more money, I believe we all understand the calculation.

Laser welding machine can also be used in sheet metal, chassis, water tank and distribution box, kitchen cabinets, stainless steel door and window guardrail, hardware products, advertising signs, arts and crafts, battery components, steel furniture, shelves and other fields.