With the expansion of the market scope, the demand for flume welding is more and more obvious, and many manufacturers have begun to look for the welding process that can replace the traditional welding process, simpler operation and efficiency. Laser welding machine on the sink welding effect is very beautiful, and the operation is convenient and fast, which is born under the premise of this rapid growth. Laser welding machine in stainless steel sink welding process efficiency has been improved many times, the effect is better than the general welding process, many enterprises are willing to use laser welding machine instead of the traditional welding process.

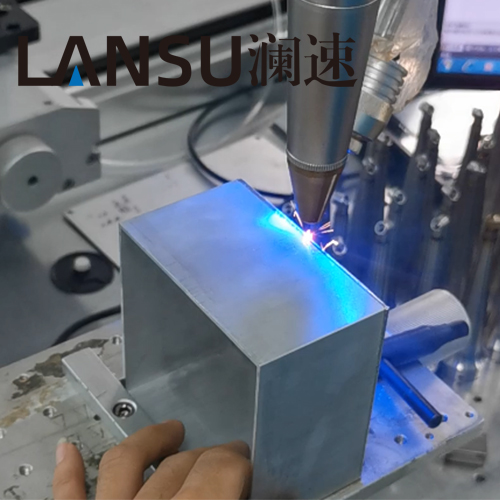

The welding of laser welding machine can realize automation, as long as in advance in the host input the set route track, the water tank is placed on the work table (multi-surface welding requires some simple mold fixed, laser welding gun can realize 360 degrees all aspects of mobile welding), laser welding machine can quickly welding the water tank. Not only simple and practical, but also, laser welding solder spot is small, color and no welding place.

The traditional welding process, the appearance of the weld is not up to standard, not beautiful, welding deformation, in the past may be barely used, but with the pursuit of more optimization of people's living standards, industrial development is more and more high-tech, the traditional welding equipment is gradually eliminated.

Traditional process welding deformation, easy to leak, follow-up need to be processed by glue, in order to ensure the use, and the process is complex, which has caused a lot of trouble to the production process of stainless steel sink, laser welding machine welding heat input is low, welding deformation is very small, can obtain a very beautiful welding surface, and welding follow-up treatment is also very little, Some even do not need secondary grinding, so the handheld stainless steel laser welding machine can greatly reduce or even eliminate polishing, save more labor costs and time costs.

Stainless steel tank laser welding machine using laser, laser power supply, internal circulation cooling system, control system, numerical control system, workbench integrated design, with reliable performance, compact structure, beautiful appearance, easy to operate, small footprint and so on. It uses a switching power supply and uses a touch panel to select the power, frequency and pulse width of the laser output. It sounds very "high-tech", but the actual operation is not complicated, but relatively simple. If it is continuous fiber welding, artificial only need to play a caretaker role, the demand for professional technology is not so high; If it is a handheld laser welding machine, novice operation can also get started in a short time, welding molding.

A single hand welding machine can equal the working efficiency of 3-6 argon arc welders in one day. Hand-held laser welding machine welding speed is faster, greatly improve the welding efficiency, but also can achieve beautiful weld, no scar, no discoloration, no need for follow-up grinding, which is why many people choose laser welding machine applied in the production and processing of stainless steel sink.