The metal dial is an important part of a watch. The quality and marking accuracy of a good watch can directly affect the price of the watch. Watches not only allow us to know the time quickly, but also become our decorations. It is like the product of the deep integration of mechanical manufacturing and clothing fashion matching, making our appearance and life more refined. Will careful netizens notice the dial on their hands? What about some model type text? Today I will talk about the application of fiber laser marking machine on metal dial.

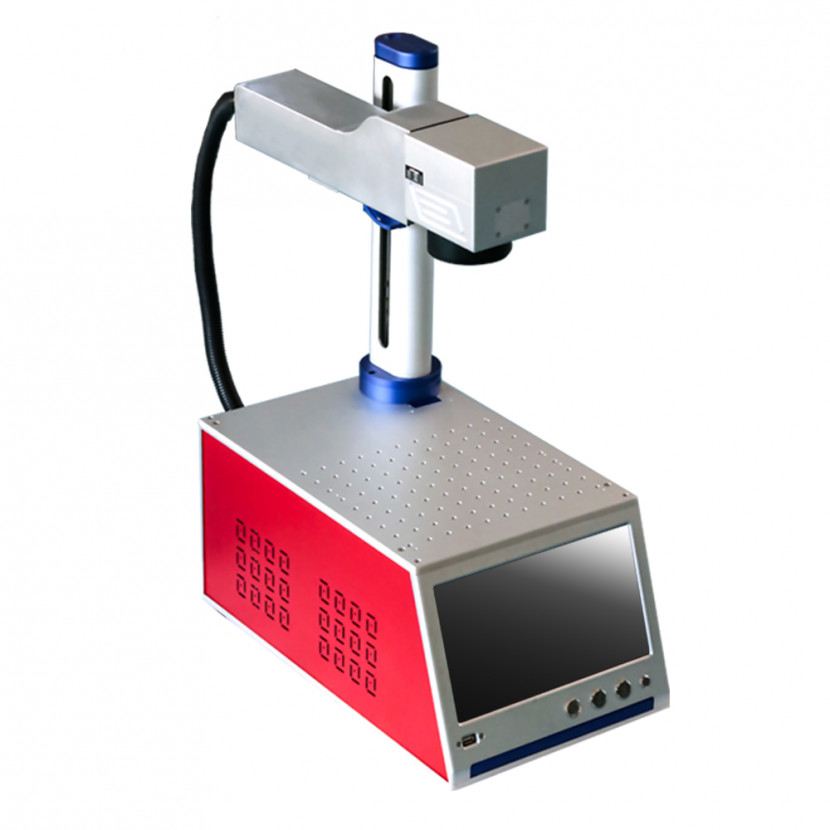

The material of the dial is generally made of metal, and the metal of the metal dial can be divided into 925 sterling silver dial and lacquered dial, and the lacquered dial is made of brass as the main material. For metal product marking, the editor recommends using fiber laser marking machine, because it is a high-precision, high-speed, non-contact laser marking equipment. The 1064nm laser beam is used to burn the surface of the dial, and there will be no damage to other parts of the dial during the burning process. The laser marking accuracy of 0.001mm makes the effect of the dial mark without any burrs and fuzziness, which satisfies people The pursuit of high quality.

In addition to marking graphics and text on the dial, the fiber laser marking machine can also mark colored fonts. If your dial is made of stainless steel, you can adjust the laser beam to change the color change of the surface layer of the material when marking, so as to obtain different decorative effects of color.

Compared with the traditional marking process, the fiber laser marking machine is a qualitative leap in the marking industry. Its characteristics of accurate marking, high efficiency and low cost make the laser marking machine not only used in the watch industry, but also in automobiles, electronics, aviation, etc. and other fields have been widely used. The editor believes that with the development of science and technology, the application of fiber laser marking machines in the field of marking will continue to expand.