Laser welding aluminum machine is more and more widely used in all walks of life, and more and more factories want to replace the existing welding tools with laser welding equipment. But I don't know if my product can be laser welded. Today we are going to introduce the application of laser welding aluminum machine in aluminum box, laser welding machine can be used for aluminum and alloy welding, and can obtain good welding results.

Laser welding machine is fully functional and powerful, the use of laser welding machine welding aluminum, on the one hand can improve the welding speed, improve production efficiency, on the other hand can reduce the heat input, improve the quality of welding, it is better than other welding equipment welding quality, is a reliable new welding equipment.

Laser welding machine before welding without polishing, directly can be laser welding, generally applicable material thickness of 1-5mm, do not need to open groove welding, aluminum alloy laser welding machine for aluminum material melting point is low, the forming is not beautiful specialized technical innovation, welding process is simple, forming beautiful, high strength. This does not need a professional welding technician, ordinary workers can be trained after the work of the tool, compared with the traditional argon arc welding operation save time and effort, now the difficult dilemma of recruiting workers believe that everyone has deep experience, slightly on the professional and technical requirements of the post are difficult to recruit the right person, ten days and a half months down will delay a lot of effort, but the operation of laser welding aluminum machine to avoid this problem.

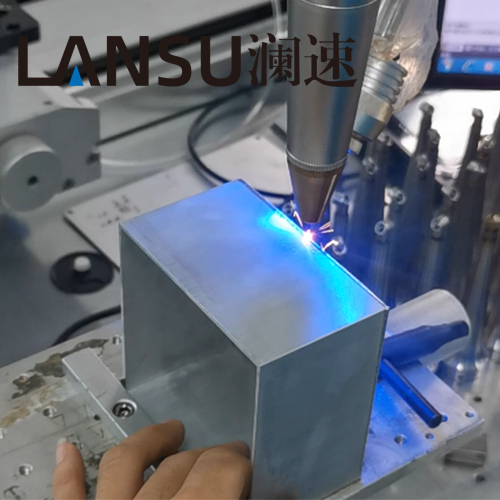

So some people will ask, can the laser welding aluminum machine also be welded on the aluminum box? Isn't the laser welding machine generally used to weld thin sheets? The reason why we have this question is often because we have ignored a problem - the flexibility and automation of laser welding.

Laser aluminum welding machine in the aluminum processing process of the welding technical parameters are more and more stringent requirements, compared with other welding methods, laser welding at the same time has the advantages of heating aggregation, small thermal damage, weld depth to width ratio is large, welding deformation is small, the welding process is easy to integrate, automation, flexibility, can achieve high speed and high precision welding, especially suitable for complex structure of high precision welding. For box welding, multi-axis or robotic configurations can be used to easily solve the problem.

In the manufacturing industry and other consumer markets, laser aluminum welding machines can replace traditional resistance spot welders. At the same time, for the traditional spot welding machine can not be welded aluminum, laser welding machine can be achieved, and can ensure good welding quality. With many advantages, laser welding machine has a broad application prospect.