With the rapid development of science and technology, many factories began to contact laser welding this technology, but the application of laser welding machine is still in a state of half-understanding, especially for "can weld aluminum alloy materials", "can weld how thick aluminum alloy" and other issues, very hope to get popular science.

Laser welding technology is a great progress in science and technology, the research of welding technology on aluminum alloy materials is now more and more in-depth, laser welding machine can weld aluminum alloy materials, because each wattage of laser welding machine welding material thickness is also different, which depends on the depth of different power laser welding machine, such as 1-3mm aluminum alloy can be easily welded through, Welding is not to mention, the thickness of 5-8mm can also be welded.

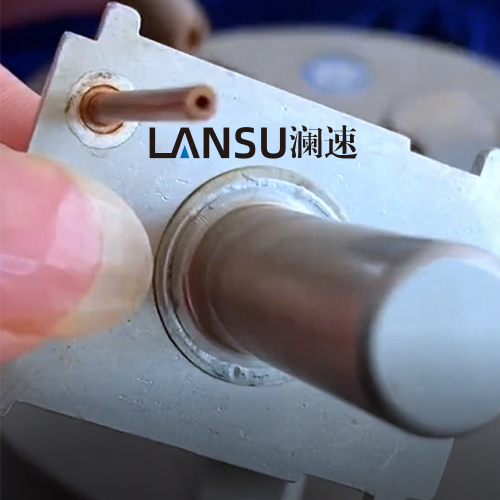

Aluminum alloy laser welding machine because the laser beam is achieved by pulsed or continuous laser beam, so when the laser beam directly irradiates the surface of the aluminum alloy, the heat of the metal surface can quickly spread to the interior of the aluminum alloy, so that the aluminum alloy quickly melts to form a weld, and at the same time, a reaction force is formed on the melted metal. The surface of the molten aluminum alloy is depressed downward to form a small hole, and the aluminum alloy welded out by laser is smooth and flat, the surface will not be rough and black, and it is easy to form once, and the operation is very simple and convenient.

It is worth noting that the aluminum alloy profile belongs to the typical eutectic aluminum alloy, which is more likely to cause thermal cracks under the rapid condensation of the metal laser welding machine, and the low solution point eutectic such as AL-Si or Mg-Si is caused by the cracks when welding the metal material crystals at the boundary of the columnar crystals. In order to reduce the thermal crack, the metal laser welding machine can be carried out by filling wire or presetting alloy powder. According to the adjustment of the laser wave mode, the manipulation of the hot key can also reduce the crystal crack.

With the improvement of the popularity of laser processing, there are many factories that use laser welding machines to weld aluminum alloy products, stainless steel, carbon steel, iron plate, silicon steel and other materials, and the heat input of laser welding machines is small and the heat source is concentrated, especially after the fiber laser welding machine is available, the energy density of laser welding is more concentrated, the laser wavelength is shorter, and the high reflection has been continuously improved.

If you also want to try to change the advanced process to improve efficiency and yield, you can consult the official website customer service, or call for consultation, we will arrange a professional manager to provide you with selection recommendations and proofing machine!