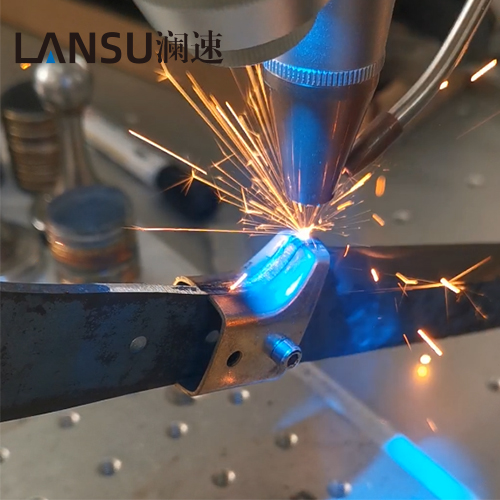

The laser welding machine transmits the laser through the optical fiber when working, and does not produce physical contact during processing, nor does it have tool wear like traditional welding equipment.

With the development and growth of laser welding machines, laser metal laser welding technology is being replaced and replaced one after another. The application of laser metal laser welding technology has changed from the initial pulse generator laser metal welding to continuous laser metal welding, and the process speed has been greatly improved.

Alloy cutting tools are processed separately for two bodies before welding. In order to meet the welding and post-welding processing of the tool, the structural design of such tools should be considered in welding and tool design. The front end of the tool tooth part and the back end of the tool handle part should be processed alloy before welding.

In order to meet the welding and post-welding processing of the tool, the structural design of such a tool should be considered in the welding and tool design. The front end of the tool tooth part and the back end of the tool handle part of the welding tool should be processed. The joint part of the welding qualified tool teeth and the tool bar should have an outstanding welding structure. Apex hole; The joint part of the welding qualified tool teeth and the tool bar should have an outstanding welding structure.

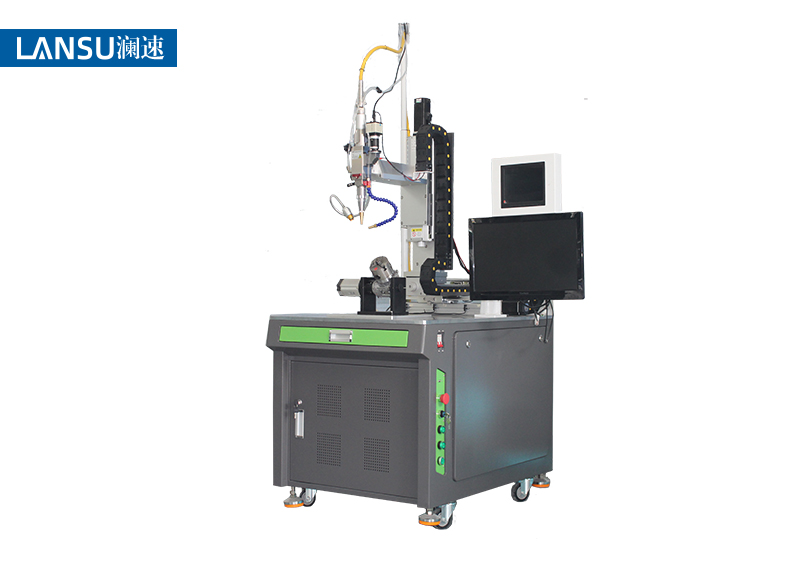

Laser welding machine is widely used in kitchen and bath industry, home appliance industry, advertising industry, mold industry, stainless steel products industry, stainless steel engineering industry, doors and Windows industry, arts and crafts industry, household goods industry, furniture industry, auto parts industry, etc.