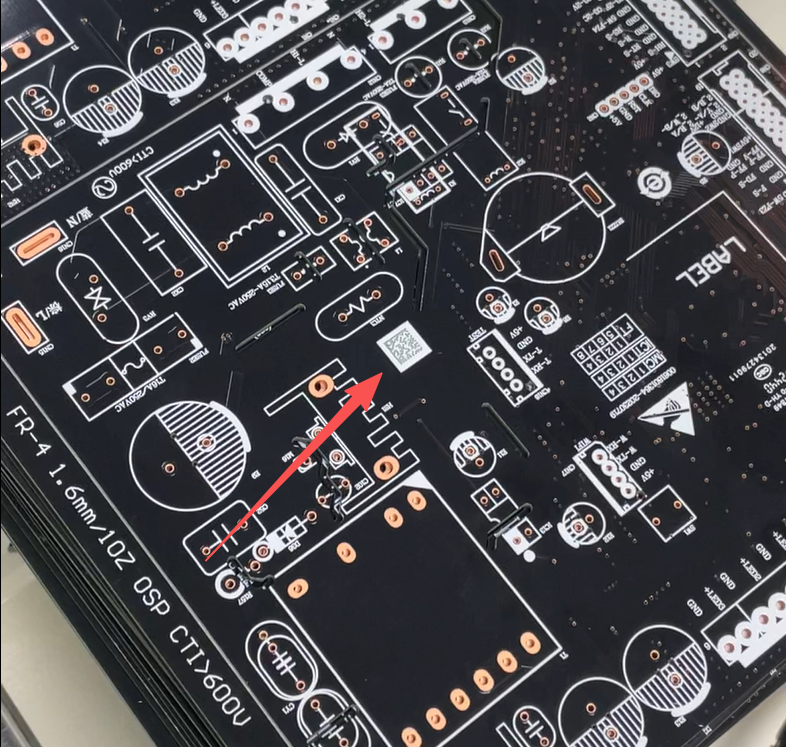

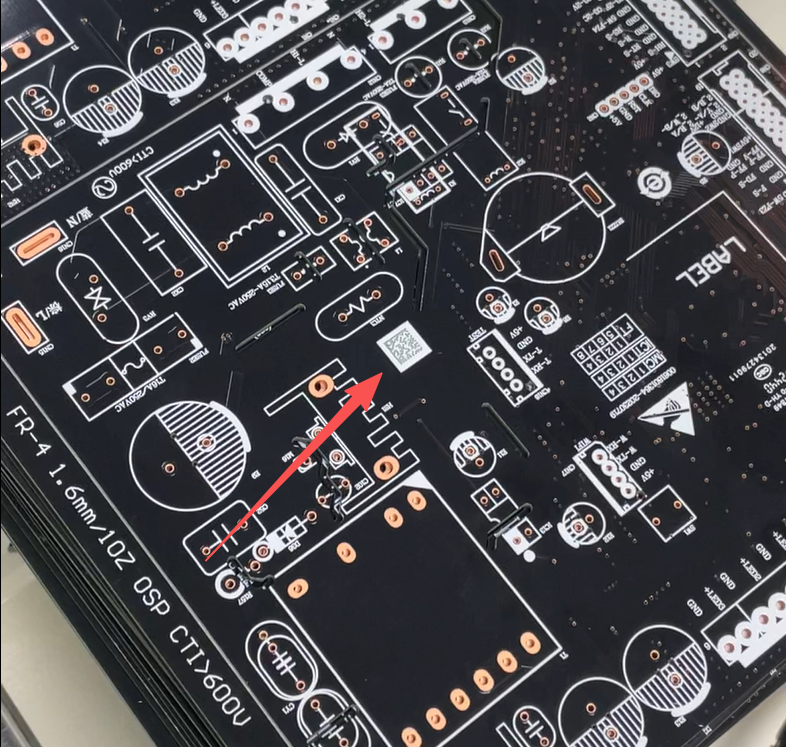

Laser marking on PCB is a process that uses a high-precision laser beam to engrave or etch QR codes, barcodes, and serial numbers directly onto the board’s surface.

The QR codes typically range from 3×3 mm to 5×5 mm, yet store complete traceability information such as product ID, batch number, and production date.

This process is non-contact, non-damaging, and highly stable, ideal for blue-oil, green-oil, and black-oil PCBs used in electronic control boards, smartphones, and automotive modules.

Advantages of Laser Marking QR Codes on PCB

1. Permanent and High-Resolution

Laser marks are wear-resistant and heat-proof, maintaining clarity throughout soldering and cleaning.

2. Non-Contact and Non-Damaging

The UV laser beam removes surface coating without physical contact, ensuring no deformation or microcracks on fine traces.

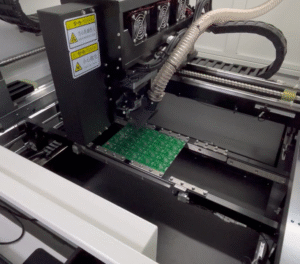

3. Seamless Automation

The laser mark PCB system integrates with SMT or AOI lines, allowing continuous automatic QR code engraving with CCD vision correction.

4. Eco-Friendly and Cost-Saving

No ink, no solvent, no label waste — reducing consumables and eliminating post-marking cleanup.

Industry Case: LansuLaser Customized PCB QR Code Laser Marking Solution

A customer from the electronics industry needed to engrave 5×5 mm QR codes on blue-oil PCB boards, and required:

- Full automation with auto loading/unloading

- CCD vision recognition for precise position correction

- Seamless integration with existing SMT line

To fulfill these needs, LansuLaser customized a UV laser marking system equipped with a vision system and conveyor docking platform, achieving automatic high-precision marking on PCBs.

🔧 Machine Specifications

| Specification | Details |

|---|---|

| Model | LansuLaser UV PCB Laser Marking Machine |

| Laser Type | 355 nm UV Laser |

| Laser Power | 3W / 5W / 10W optional |

| Marking Area | 110×110 mm / 150×150 mm (optional) |

| Marking Speed | ≤ 7000 mm/s |

| Positioning Accuracy | ±0.01 mm |

| Marking Depth | 0.01 – 0.03 mm (adjustable) |

| Supported Code Types | QR Code, DataMatrix, Serial Number, Text, Logo |

| Vision System | Industrial CCD Camera with automatic position correction |

| Cooling Method | Air Cooling / Water Cooling (optional) |

| Automation Interface | Conveyor docking platform with PLC I/O connection |

| Power Supply | AC 220V ±10%, 50Hz |

| Software | EZCAD + MES data communication support |

⚙️ Typical Marking Parameters

| Material Type | Laser Power | Frequency | Speed | Focus Size | Result |

|---|---|---|---|---|---|

| Blue-Oil PCB | 3W UV | 30 kHz | 400 mm/s | 0.015 mm | Clear white QR code |

| Green-Oil PCB | 5W UV | 35 kHz | 500 mm/s | 0.02 mm | High contrast, no charring |

| Black-Oil PCB | 10W UV | 40 kHz | 600 mm/s | 0.02 mm | Sharp gray-white mark |

| FR-4 Material | 3W UV | 25 kHz | 350 mm/s | 0.015 mm | Smooth engraving edges |

(Parameters may vary depending on surface coating and line speed.)

System Highlights

✅ CCD automatic vision positioning for precise QR alignment

✅ Fully automated loading/unloading with conveyor interface

✅ Real-time MES data communication for traceability

✅ Continuous high-speed operation for SMT production lines

After installation, the customer achieved:

- 40% faster production efficiency

- 100% QR code readability

- Zero PCB damage or misalignment

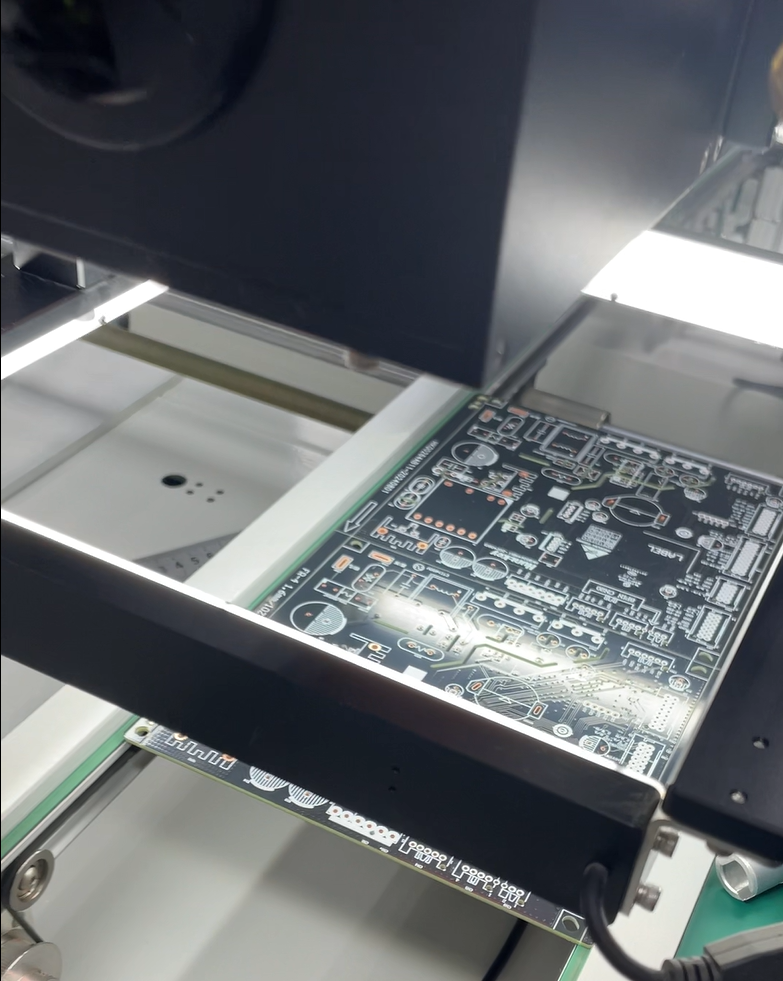

(Insert image: “lansulaser-pcb-qr-code-laser-marking-machine.jpg”)

Why Choose LansuLaser

As a professional laser marking machine manufacturer in China, LansuLaser provides fully customized UV laser mark PCB systems designed for industrial automation.

🔹 10+ years of experience in laser marking automation

🔹 CE-certified with global after-sales support

🔹 Factory-direct customization and competitive pricing

🔹 Integration-ready with AOI, SMT, and MES systems

Conclusion

Laser marking QR code on PCB has become the industry standard for digital traceability.

It ensures every circuit board is identifiable, supports smart manufacturing, and improves long-term reliability.

If your factory requires precise, automated, and stable PCB QR code marking, contact LansuLaser for a tailor-made UV laser marking solution.

Contact LansuLaser

🌐 Website: lansulaser.com

📞 WhatsApp: +86 18925707676

📧 Email: info@lansulaser.com