Some aluminum alloy materials need to identify relevant data information in the processing process, then as a laser equipment manufacturers in aluminum alloy marking recommended the use of laser marking machine, which can be used as both identification equipment and drilling equipment, to achieve a product multi-functional use.

As a common material, aluminum alloy tube is widely used in aerospace, automotive, electronics and other fields. In these fields, the marking of aluminum alloy tubes is a very important process. Traditional marking technology such as sandblasting, chemical etching, etc., there are problems such as unclear marking and environmental pollution, and laser marking machine can better solve these problems.

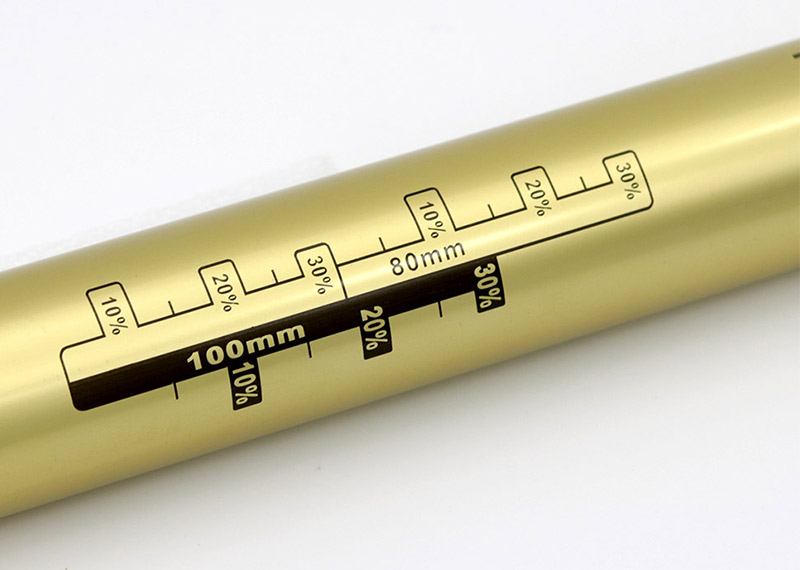

Lansu Laser recently learned about a customer's needs: they want to mark the two-dimensional code at the bottom of the aluminum alloy round tube and punch holes, but they need a device to complete it.

Therefore, when using the laser marking machine to identify the two-dimensional code on the aluminum alloy, it is necessary to choose the appropriate laser type and power according to the type, thickness and surface treatment of the aluminum alloy. At the same time, we also need to choose the appropriate processing parameters and process methods according to the size and accuracy requirements of the two-dimensional code. In general, we can verify the performance and effect of the laser marking machine through the sample to ensure that the product meets our requirements.

In addition to identifying the QR code, it is necessary to punch holes at the bottom. It is necessary to punch holes on aluminum alloy with a diameter and thickness of 1MM, we recommend the use of 30W fiber laser marking machine, but the punching process can be easily achieved.

It is worth noting that the surface of the aluminum alloy needs to be treated so that the laser beam can reflect back effectively and generate enough heat to melt or vaporize the surface material. Second, the QR code needs to be carefully designed and optimized to produce a clear, beautiful image on the surface of the aluminum alloy. Therefore, it is necessary to use the appropriate laser and parameters in order to produce the ideal marking effect on the aluminum alloy.