As a new marking technology, laser marking machine is favored by PCB manufacturers, because of its efficiency, high speed, clarity and other functions, it brings great advantages to PCB manufacturers.

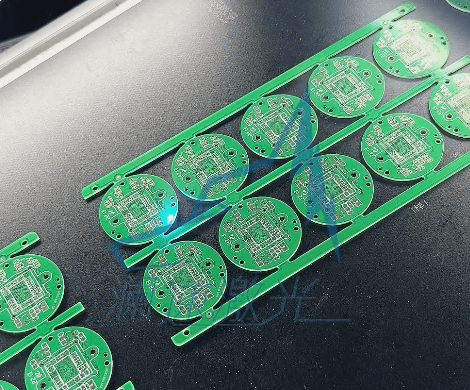

PCB board, also called circuit board, is a provider of electrical connections for electronic components and a core component of electronic equipment. As a core material, it is used in medical equipment, industrial equipment, lighting industry, automotive core accessories, 3C electronics industry, aerospace, etc. Industry and other multi-industry applications. Then the marking process of PCB in manufacturing cannot be sloppy.

However, the laser marking machine can just mark two-dimensional codes, barcodes, production dates, usage information, etc. on the PCB. The 355nm cold light laser can use the laser beam to burn marks on the surface of the PCB without touching the surface of the product, so as to achieve the effect of marking. So what are the application advantages of cooperation between laser equipment and the PCB industry?

1. High-precision marking technology. The traditional marking method is more dependent on manual operation, which is very prone to problems such as position deviation, blurred fonts and ghosting, which will affect the quality and reliability of the product. Laser marking equipment can clearly and accurately engrave on PCBs through laser beam irradiation, whether it is small fonts or complex graphics.

2. Improve production efficiency. The laser marking machine can be upgraded to automatic marking, which can realize mass production and personalized customization requirements, and perform fast and precise identification according to different product requirements. This high-speed production mode helps manufacturing to reduce costs and improve product competitiveness.

3. Anti-counterfeiting application. As we all know, fake and inferior products have a very large negative impact on consumers and genuine manufacturers, which will not only reduce the sense of use but also reduce the reputation of the manufacturer. Laser marking anti-counterfeiting marks can effectively prevent such things from happening.

Therefore, the advantages of laser marking machines in PCB manufacturing are obvious. If you want to know about similar products, you can leave a message on the editor's website or contact us by phone. The editor will help you answer your doubts online 24 hours a day.