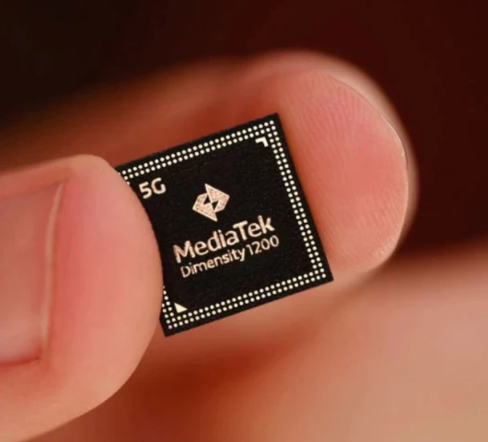

With the development of science and technology, the major mobile phone operators bring forth the new, research and development and production of a lot of new mobile phones, chips as the core components of mobile phone research and development, its manufacturing and processing process has caused widespread concern, such a tiny chip can be carved with laser marking machine?

Laser marking machine is a technology that uses a high-energy laser beam to illuminate the surface of an object, so that the surface of the material quickly melts, vaporizes or reaches the ignition point, and at the same time blows away the particles that splash up with high-speed airflow, thereby leaving marks on the surface of the object.

We need to understand the basic structure and manufacturing process of mobile phone chips. Cell phone chips are mainly made of semiconductor materials, go through a series of complex manufacturing processes, and then play a role in processing and transmitting data in the phone. In this process, chip manufacturing involves operations at multiple microscopic levels, such as lithography, doping, and thin film deposition. These operations have very high requirements on the environment and equipment, requiring strict control of temperature, humidity, pressure and other parameters.

Laser marking machine has the following advantages in the chip manufacturing process:

1, high precision: you can use high precision on the chip engraving patterns and text, accuracy up to micron level.

2, no contact: the use of non-contact processing, will not cause mechanical pressure on the chip surface, to avoid scratches, pollution and other problems.

3, fast speed: laser marking machine has high-speed scanning and pulse energy control ability, can complete a large area of engraving task in a short time.

4, safety: laser marking equipment will not produce toxic substances or noise during work, providing a good working environment for workers and the environment.

5, traceability: through the laser engraving pattern and text can clearly identify and trace the production batch, production date and other information.

In addition, the processing stability and reliability of the laser marking machine are also factors that need to be considered. Any mistake in the manufacturing of mobile phone chips can cause the chip to fail. Therefore, the stability and reliability of the equipment need to be fully guaranteed to avoid unexpected situations in the manufacturing process.