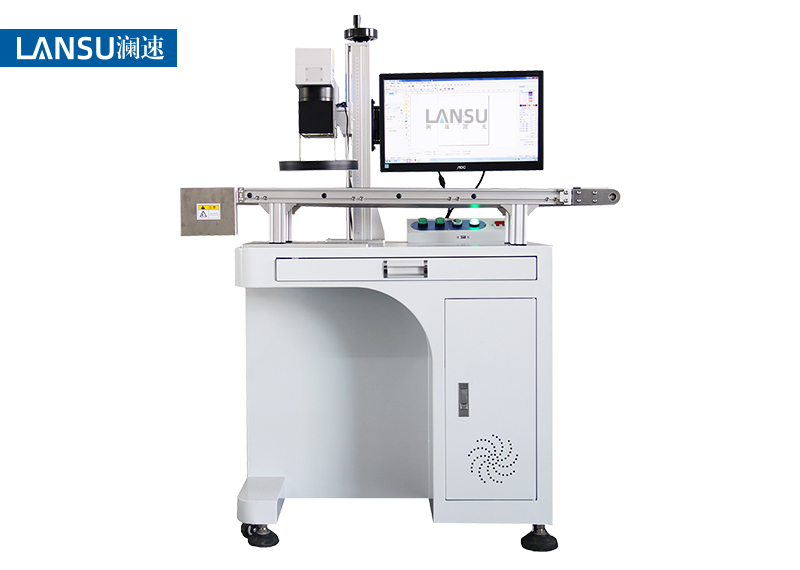

With the intelligent and diversified development of society, the laser industry has also undergone earth-changing changes, and the laser marking machine has also been upgraded to a fully automatic laser marking machine, mainly changes in production capacity, identification speed, unmanned, etc., let's discuss the equipment together.

Automatic laser marking machine, also known as automatic laser marking machine, specifically for the mass production of different models of products, its main advantage is that it can be mass produced in a short time and shorten the delivery time, can be marked in multiple locations of the same product at the same time, is a huge improvement in the laser marking industry. This model adopts the imported high-speed vibration and ytterbium scanning system, which gives the signal from the radio and television sensory signal to trigger the laser to carry out the visual line marking operation, and adopts the customized marking control system to realize the identification of the date, time, model, batch number, LOGO, pictures and other contents of the assembly line products.

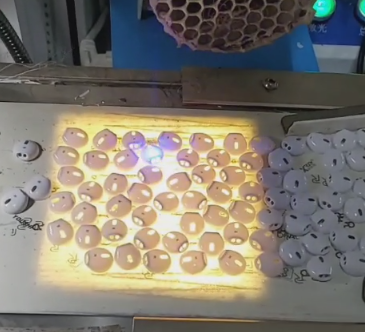

For small plastic type products, the automatic laser marking machine is used to identify the appropriate plastic products, but after the transmission belt is transported down from the previous process, there is no need to manually place them, and the products can be automatically arranged in an orderly manner through the automatic correction position of the "vibration disk", and the process of the laser marking machine is transmitted one by one.

When transmitted to the bottom of the laser head, the CCD visual detection system of the laser marking machine will go through the "product shooting - identification positioning - operation marking" in just a few tenths of a second, marking the edited content of the product. There is no need for manual participation in the whole process, and the products are automatically delivered to the next process through the assembly line after they are marked. Customers no longer have to worry about frequent rework of products due to blurred logos; There is no need to worry that the production capacity can not keep up with the delivery date, and overtime will affect the production plan.

Automatic laser marking machine is very suitable for the production of 3C electronic products, enterprises through the establishment of intelligent manufacturing production lines to improve production efficiency and reduce labor costs. The automation equipment of Lansu laser equipment production enables enterprises to mark products in the production process to achieve product supply chain tracking and product quality traceability solutions.