First of all, let's take a look at the principle of peeling paint on the mobile phone camera: The device used for stripping paint on the mobile phone camera is ultraviolet laser marking, which uses 355nm high-energy cold light laser beam to illuminate the surface of the outer ring of the camera, so that the coating and paint on the surface of the outer ring are melted, vaporized or reached the ignition point in an instant, and at the same time remove it in a rapid way, so as to achieve any visible pattern, text, background color and other purposes on the surface of the object.

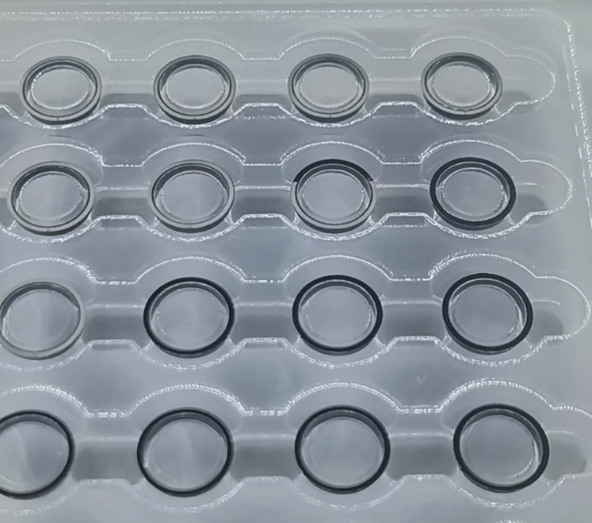

So, why can the laser marking machine make the mobile phone camera remove paint in one second? In fact, this is mainly because the marking speed of the laser marking machine is very fast, and the data shows that in the identification of a large number of products, the marking speed can reach 7000mm/s, and the accuracy can be as high as 0.01MM. Can strip paint and mark smaller products, pulse width range of 13-80ns. Therefore, the paint can be removed in one second on the edge of the outer ring of the phone camera.

The magic of this technology is that it not only greatly improves work efficiency, but also does not have any impact on the material of the phone's camera itself. Because the high energy laser beam of the laser marking machine has the characteristics of high precision, high speed and efficiency, it can complete the marking work of a large area in a short time, and will not cause damage to the object itself.

In addition, this technology has another advantage, that is environmental protection. Because the laser marking machine does not produce any harmful substances during the working process, it is a very environmentally friendly technology. Moreover, due to its high efficiency, it can also reduce energy consumption and achieve green production.

Compared with the traditional paint removal technology, the advantages of this new laser marking machine identification technology are its speed, accuracy and efficiency. The traditional paint removal method usually requires the use of chemical reagents or physical friction, which not only takes a long time to process, but also easily causes damage to the surface of the object. This new laser paint removal technology can be completed in a short time, and the damage to the surface of the object is almost negligible.