The continuous progress of science and technology makes the manufacturing industry move towards a more prosperous development path, and the laser marking machine has gradually become an important production equipment in all walks of life. Among them, ultraviolet laser marking machine with its unique advantages, more and more attention in the application of silicone pen marking.

First, what is UV marking machine?

Ultraviolet laser marking machine is a device that uses ultraviolet laser beam of 355nm wavelength to mark the surface of materials. It works by shining a high-energy ultraviolet laser beam onto the surface of the material, causing the material to undergo a photochemical reaction, thus forming a persistent mark on the surface of the material that will not fade. Because of its high precision, high speed and high efficiency, it is widely used in various fields.

Second, the marking application of silicone pen

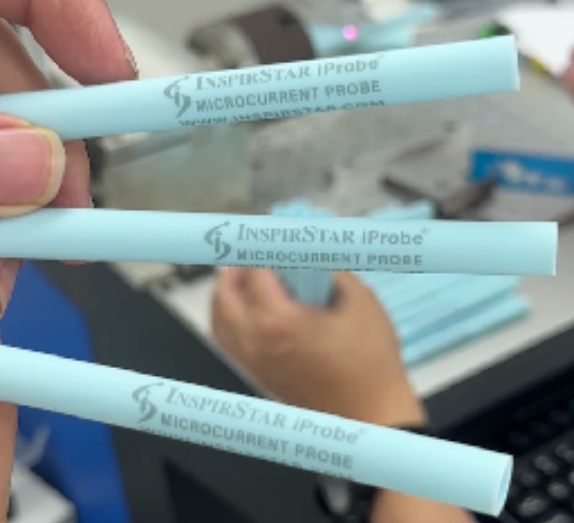

Silica gel pen is a kind of writing instrument made of silica gel material, which is soft, durable, and not easy to wear. Its material is silica gel, and because the shape is a cylinder, it is often necessary to mark half a circle or a circle, and it is difficult to achieve the effect with the general screen printing or inkjet method, so the UV laser marking machine is often used in manufacturing.

Third, the application advantages of ultraviolet laser marking machine on silicone pens

1, marking speed is fast, marking method is flexible

Uv laser marking machine uses high-energy ultraviolet laser beam to process the surface of the silicone pen, marking speed can be up to 7000mm/s, can complete a large number of marking work in a short time. At the same time, for the silicone pen that needs to mark a whole circle, you can use the automatic rotating table without manual rotation, and some products with curved surfaces can also use 3D lenses for marking.

2, the marking effect is good

The mark formed by UV marking machine on the surface of the silicone pen is clear, beautiful and not easy to wear. Screen printing is not wear-resistant, it will soon be worn off the logo, and it is easy to print blurring, double shadow, missing words and other bad effects, but the laser marking can be maintained for a long time, and the rate of good products is high. At the same time, due to its non-contact marking method, it will not cause any damage to the surface of the silicone pen.

3, wide range of application

Uv laser marking machine can be applied not only to the marking of silicone pens, but also to the surface treatment of various other materials. Such as metal material, ABS, PVC, PC, PP, glass, wood, EVA, Mara tape, PI film, chip, etc., a machine universal, cost-effective!

Iv. Summary

In summary, UV marking machine has great advantages in the marking application of silicone pens. Precision up to 0.02mm, no ink consumables, can greatly improve production efficiency, but also to meet the needs of different customers, such as combined with the transmission belt, fully automated visual positioning marking, saving several labor. Therefore, with the continuous progress of science and technology and the continuous expansion of application fields, ultraviolet laser marking machine will be applied in more fields.