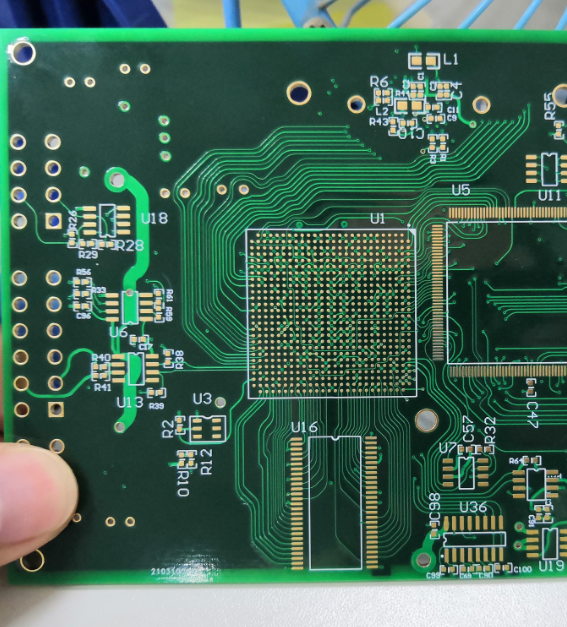

PCB is the core parts of electronic components, it is directly connected to the internal parts of electronic products, there are many complex processes in the production process, among which the use of laser marking machine to carry out two-dimensional code information identification becomes the top priority.

With the rapid development of laser equipment, the effect of laser marking machine is favored by many people. It can be said that it can largely replace the traditional silk screen processing method. Because of its rough marking effect, easy to fall off, unable to identify smaller PCB board and other shortcomings, many manufacturers want to update the iteration of the reason. So what are the advantages of laser marking machine to become the right-hand man of PCB board identification?

1, no contact. Laser marking machine is the use of high energy density laser on PCB board for local irradiation, so that the surface material vaporization or discoloration, this non-contact processing, can be marked in a very small format very clear two-dimensional code, to ensure high precision but also to ensure high quality, will not wear due to high and low temperature, acid alkaline change and external friction.

2. Good marking effect, high precision and efficiency. After the laser beam is focused, the spot diameter of the laser beam can reach 10um (UV laser), which has small and large benefits in the processing of complex graphics and fine processing. Using only need to set the parameters on the computer system can be marked directly, in just a few seconds to more than ten seconds to complete the material surface marking.

3, stable performance, no consumables. Generally, maintenance rarely occurs after the purchase of laser marking machine. Each laser equipment of Lanlan laser equipment production factory needs to be aged before leaving the factory, to ensure that each equipment does not have any problems before it can be sent to the destination. In addition, there is no consumable in the marking process of the equipment, so there is no need to pay additional consumable fees.

Laser marking machine combined with PCB involved in aerospace, medical equipment, 3C electronics, automotive and other industries, clear identification technology, accurate wipe board. At the same time, the quality and information can be traced to the source, to help enterprises realize the intelligent management needs.