An electric toothbrush is a common small electrical appliance in modern homes. Its shell is usually made of plastic to package and protect the shell of electronic equipment. The commonly used materials are ABS, PC, PP, etc. These materials have excellent processing performance and mechanical properties, which can meet the manufacturing requirements of the electric toothbrush shell. At the same time, these materials have wear resistance, high temperature resistance and chemical stability, which can protect the electronic components inside the electric toothbrush and extend the life of the electric toothbrush. service life. Today, the editor will take you to understand how the laser marking machine performs fine marking on the shell of the electric toothbrush.

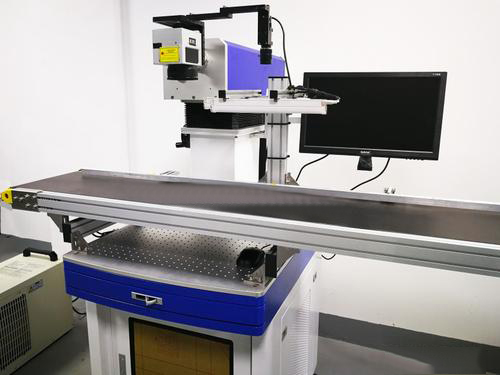

The laser marking machine carves clear and accurate patterns and characters on the surface of the electric toothbrush shell by focusing the laser beam, so as to realize the function of marking. Compared with traditional spraying and printing technologies, laser marking technology not only has higher precision and efficiency, but also does not produce pollution and poison, and is more environmentally friendly.

Generally speaking, we use ultraviolet laser engraving machine to mark the electronic toothbrush shell, because the laser wavelength of 355nm can make the laser beam more focused than the infrared laser beam of 1064nm, so the marking effect is the same as the original shell . The marking range can also be adjusted according to the needs of the product. Generally, the marking range of the UV laser marking machine is 150MM*150MM. If your product identification interview is relatively wide, you can choose a large-scene high-power equipment for marking to ensure Identify requirements.

After satisfying the marking accuracy and range, many netizens are more interested in the marking speed. The marking speed of the purple light machine will not disappoint everyone. The speed is usually between 6000-10000 mm/s. With the automation scheme, this speed High efficiency and mass production can be realized. The higher the pulse repetition frequency of the UV laser marking machine, the faster the marking speed, but the power will decrease. Typically, the pulse repetition frequency is between 10-200 kHz. Compared with the traditional marking technology, it cannot meet the needs of electric toothbrush shell marking, and the application of laser marking machine has injected new technological elements into the electric toothbrush shell marking, making the product more refined and intelligent.

In addition to the application in the marking of electric toothbrush shells, laser marking machines can also be used in other industries, such as electronics, automobiles, aerospace and other fields, to inject higher technological content and quality assurance into products. Generally speaking, the application of laser marking technology is the future development trend. Its application in the marking of electric toothbrush shells has injected technology and intelligent elements into the entire industry. It is believed that in the future development, laser marking technology will bring more